- Home

- リソース

- ヒントとコツ

Tips & Tricks

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

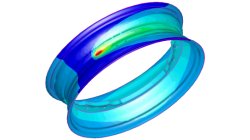

The transient method – the third out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The third one – the transient method – is used when not only distortion but also residual stresses and microstructure need to be evaluated. The part size allows running a heat source gradually. Compare it with a formability evaluation in sheet metal forming. A motorcycle rim may serve as an example.

Harald

Porzner

Welding & Assembly

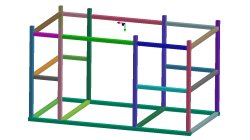

The instantaneous method – the second out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The second one – the instantaneous method – is used when not only distortion but also residual stresses and micro-structure needs to be evaluated, but welded designs are so huge that it would make no more sense to use a classic transient method with a moving heat source – the simulation time would be too long. Compare it with a feasibility evaluation in sheet metal forming. A frame as produced in machine building, with more than 100 welds, may serve as an example.

Harald

Porzner

Welding & Assembly

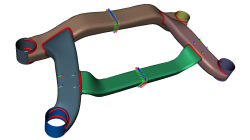

The shrinkage method – the first out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The first one – the shrinkage method – is used in the feasibility and planning phase. Goal is to get as fast as possible an estimation. Compare it with a one-step method in sheet metal forming.

Harald

Porzner

Welding & Assembly

How to fix grey selection window in PAM-STAMP GUI ?

Using default setup of AERO themes in Windows 7 and Vista creates problems for selection by window in PAM-STAMP GUI. There are instructions how to setup your Windows to avoid that problem.

Vladimír

Cerny

Sheet Metal Forming

Make an independent setup from existing pre and rst files in PAM-STAMP

Sometimes only rst files there are available and dependent pre file of an intermediate stage setup (lost data, picking with a process variant, …), which is not possible to run in another PAM-STAMP version, usually in newer version. It is possible to create a pre file independent on preceding rst files.

Tomas

Nosek

Sheet Metal Forming

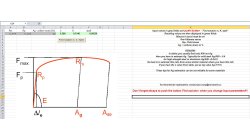

Determination of Krupkowsky parameters for hardening curve

In case there are no measured material data for simulation purposes, it is possible to determine hardening curve from information usually provided by material supplier.

Tomas

Nosek

Sheet Metal Forming

How to import a PAM-STAMP result into CATIA V5 with VRML export format ?

For a comparison of the virtual stamped part and the nominal CATIA V5 part one can use PAM-STAMP, or go back to CATIA. Since the meshed part is not easily converted into surfaces again, one solution is to use an overlay of the CAD part and of a VRML export of the stamp part.

Matthias

Schroeder

Sheet Metal Forming

How to encrypt material data sets in PAM-STAMP?

Major automotive companies spend a lot of money to describe all materials used in their simulation processes. To ensure simulation quality also at supplier sites, they want to give the material data sets to them, but not for free. One half of the solution is material encryption, the other a predefined expiration date.

Matthias

Schroeder

Sheet Metal Forming

Small collection of 3D meshed symbols for illustration purposes

During a project the need to visualize the functionality in 3D arose and some 3D symbols were created, which are now made available as a goody.

Matthias

Schroeder

Sheet Metal Forming