- Home

- リソース

- ヒントとコツ

Tips & Tricks

How to Obtain Best Results within Reasonable Time from a Heat Treatment Simulation

Heat treated parts are in most cases not clamped during heat treatment, for an FEM analysis, at least a static determined clamping is needed that does not allow any rigid body motion.

Yonggang

Duan

Welding & Assembly

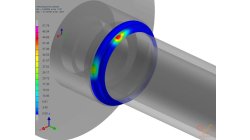

Stamping/HT Chaining of 3D Ring - Restart tool in Visual Heat Treatment

This article is to show effects of heat treatment on stresses when industrial mechanical parts are stamped (or welded) by 3 typical heat treatment steps: Heating, Quenching and Tempering. Tempering is generally considered effective in relieving stresses induced by quenching in addition to lowering hardness to within a specified range, or meeting certain mechanical property requirements.

Yonggang

Duan

Welding & Assembly

Heat Power display in Visual Weld

The aim of this development in Visual Weld 14.5 + Sysweld 2019.0 is to display the Power Density. Currently, this functionality is only available in the old SysWeld GUI. The new functionality "Heat Power Display" is available through the "Welding Utilities" menu of Visual Weld.

Yonggang

Duan

Welding & Assembly

Conversion Files .fdb in .erfh5 on Network Drive

It is not straightforward to do the conversion Files .fdb in .erfh5 on Network Drive in Visual Viewer. In order to make it work properly, it is necessary to map network drive to the local machine. In this way, the files on network could be handled like on local machine and the conversion from fdb to erf will be working properly.

Yonggang

Duan

Multiphysics, Welding & Assembly

Crash when launching Visual on CentOS

On Linux, at moment of launching Visual-Environmnet, crash happens after having selected Visual Weld. It is possible to try following steps to solve the problem. - Launching Visual in debug mode - Downgrade GlibC to 2.12 - Install freshly NTP

Yonggang

Duan

Virtual Integration Platform, Welding & Assembly

Boundary Layer Mesh tool demonstration

Easily creating a connection between a tetramesh and an hexamesh is possible, using Boundary Layer Mesh tool.

Sandrine

Dischert

Multiphysics, Welding & Assembly, Virtual Integration Platform

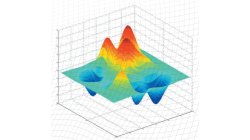

Process optimization: the future of numerical simulation software

Optimization is becoming a very popular word. However, what does it mean and what does it involve? The goal of this e-tip is to give some keys about optimization concepts and its use in process optimization. In a first stage, we will describe the type of optimization problems that could be solved and in a second stage, the principles and algorithms will be presented. Finally, advantages and drawbacks of the different methods and algorithms will be addressed, with respect to the different types of optimization problems which can be solved.

Casting

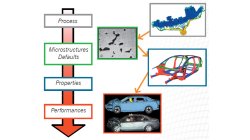

Casting simulation: from prototype to performance

Passenger safety in cars, planes and other transportation vehicles is an ethical obligation, a legal issue and a technological challenge. Simulation is a well implemented tool in order to test the behaviour of a car body during crash. The models, including rapid deformation and rupture, are sophisticated and reliable. Currently, most properties used in such simulations correspond to homogenous and defect free materials. However, cars are manufactured before being crashed. And manufacturing routes such as casting, but also stamping, forging or welding, do not provide defect free and homogeneous materials.

Casting

Parallel processing

“To pull a bigger wagon, it is easier to add more horses than to grow a gigantic horse.” This paraphrased quotation nicely expresses the basic concept of parallel processing. The speed of sequential computers has been doubling every eighteen months, according to Moore’s law. However, at any given time, that speed is limited by the state of the art in integrated circuit design and manufacturing. To circumvent that limitation, it is possible to split a given computationally intensive task among multiple processors working simultaneously.

Bohus

Ulrych

Casting

Critical issues in modelling investment casting

Reduce part development lead-times by a better knowledge of process and an early confi rmation of metallurgical capabilities is one of the main topics for investment casting technology. Numerical simulation is one of the major tools which can be used to face this goal. This e-tip illustrates a simulation methodology usable to optimize a casting design in an effi cient and rapid way.

Casting