- Home

- リソース

- ヒントとコツ

Tips & Tricks

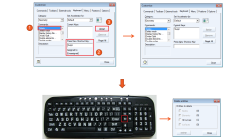

How to create and share keyboard shortcut keys?

Tips and tricks to help users to create and share their shortcut keys in PAM-STAMP

Benoît

Muller

Sheet Metal Forming

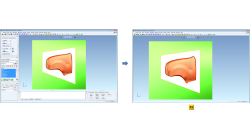

How to maximize active view in PAM-STAMP GUI?

Shortcut to maximize the active view

Benoît

Muller

Sheet Metal Forming

How to automatically fill the Multi-Hosts options in PAM-STAMP GUI?

This tips is to help users to have the multi-hosts automatically filled in a several stages project when they want to start a calculation in PAM-STAMP GUI.

Benoît

Muller

Sheet Metal Forming

How to run a multi-stages project on Windows with a Single host in PAM-STAMP GUI?

This tip is to help users to run a calculation by using only one automatic host, even if it is a multi-stage project.

Benoît

Muller

Sheet Metal Forming

How to Copy/Paste images from PAM-STAMP GUI ?

Shortcuts key to copy/paste images quickly from PAM-STAMP GUI into a presentation.

Benoît

Muller

Sheet Metal Forming

How to create your own toolbar in PAM-STAMP?

This tutorial is to help users to create their own custom toolbar, and then to shows how to share it with others.

Benoît

Muller

Sheet Metal Forming

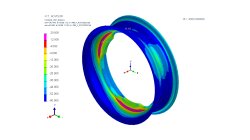

Weld Fatigue analysis based on the Dang Van Criteria

Numerical modeling of fatigue behavior has become critical for welding applications. For this purpose the ‘Dang Van criterion’ has been integrated in SYSWELD for fatigue evaluation of welded structure under multi-axial loadings. The Dang Van fatigue damage criterion is used to predict crack initiation and life duration of components subjected to damaging load. This criterion is based on multi-scale approach which assumes that shakedown occurs before crack initiation.

Harald

Porzner

Welding & Assembly

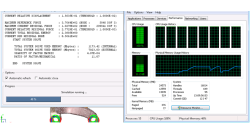

How to report and talk about simulation time in an objective manner

Reporting or talking about simulation time is a difficult subject. In the article a way to manage this problem in an objective manner is given.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

The transient method – the third out of three methods to simulate the heat effects of welding

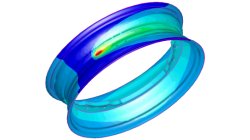

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The third one – the transient method – is used when not only distortion but also residual stresses and microstructure need to be evaluated. The part size allows running a heat source gradually. Compare it with a formability evaluation in sheet metal forming. A motorcycle rim may serve as an example.

Harald

Porzner

Welding & Assembly