- Home

- リソース

- ヒントとコツ

Tips & Tricks

How do I create an SEA cavity using shrinkwrap?

How to create FE acoustic cavities with complex shapes

Ricardo

Alvarez

CFD, Vibro-Acoustics

Static comfort – Different encrypted data display

How to display encrypted occupant when other data are also encrypted in the model.

Virtual Seat

Static Comfort - Sensors Grid

Sensors Grid Definition improvement in Virtual Seat Solution v2015 (VE 11)

Cécile

Cabane

Virtual Seat

Trim Manufacturing – Trim Adviser

Trim Adviser improvement in Virtual Seat Solution v2015 (VE 11)

Cécile

Cabane

Virtual Seat

Auto Empty Folders option in CFD-GEOM

When importing large models into CFD-GEOM, you may notice that certain entities listed in the Model Manager may have a red box around them.

Abraham

Meganathan

CFD

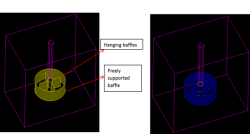

Adding Baffles to an Unstructured domain in CFD-GEOM

While meshing the geometries of industrial significance like mixing tanks, reactor and heat exchangers, we may encounter baffles which have negligible thickness but significant area to impact the physics of the problem in terms of momentum and heat transfer. These surfaces may be free-standing or connected to other surfaces from the domain.

Abraham

Meganathan

CFD

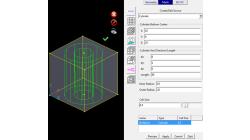

New Mesh Sources in CFD-GEOM for Triangle and Tetrahedral meshing

Corner Point Sources, Surface Interior Sources and Tet Sources have been available in CFD-GEOM for several years, allowing for refinements during certain phases of mesh generation.

Abraham

Meganathan

CFD

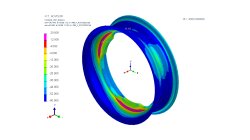

Weld Fatigue analysis based on the Dang Van Criteria

Numerical modeling of fatigue behavior has become critical for welding applications. For this purpose the ‘Dang Van criterion’ has been integrated in SYSWELD for fatigue evaluation of welded structure under multi-axial loadings. The Dang Van fatigue damage criterion is used to predict crack initiation and life duration of components subjected to damaging load. This criterion is based on multi-scale approach which assumes that shakedown occurs before crack initiation.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

The challenge of simulating casting and heat treatment

Foundries that have implemented casting simulation to shorten development time, further wish to use simulation in order to reduce the cost of subsequent processing steps. This often requires the simulation of heat treatment.

Casting, Welding & Assembly