PAM-STAMP - Hemming and Assembly

Learn how to perform hemming and assembly simulation using the PAM-STAMP solution, which covers the entire tooling process to formability and try-out validation.

Audience

CAE engineers, model designers, etc

Prerequisites

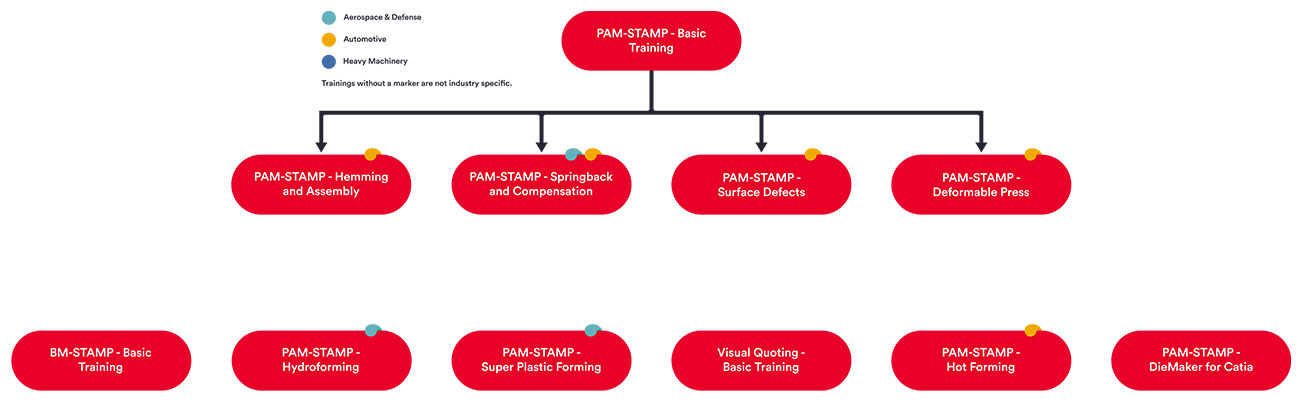

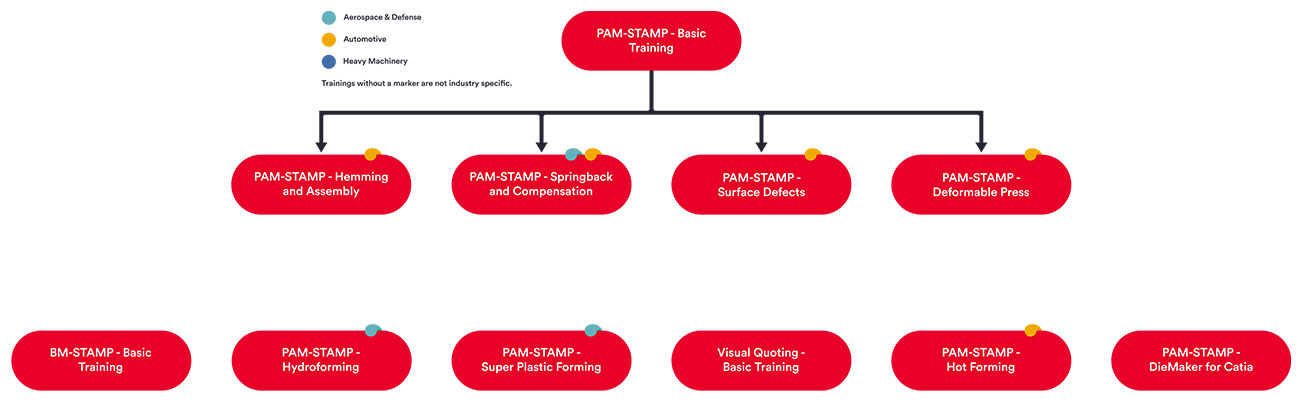

LEARNING PATH

SUGGESTED COURSES

概要

This course focuses on advanced processes using PAM-STAMP solution (Graphical user interface, process setup for fast feasibility, and production validation). Participants learn to prepare Hemming and Assembly models, run simulations, and evaluate results via the PAM-STAMP Graphical User Interface.

お探しのものが見つかりませんでしたか?

カスタマイズトレーニングを依頼

TRAINING PROGRAM

Day 1 - Table-Top Hemming

- Mesh preparation of project part (Nominal)

- Tabletop setup with stamp history

- Gravities (outer and inner)

- Pad closing

- Steel 45° and 0°

- Springback over die blocks

- Post-processing

Day 2 - Roll Hemming

- Introduction

- Roll Hemming setup with stamp history

- Gravities (outer and inner)

- Pad closing

- Robot path definition (3 path)

- Springback over die blocks

- Post-processing

Day 3 - Stop Welding

- Introduction

- Clamping and joining setup with stamp history

- Simultaneous closing

- Sequential closing

- Springback over die block after joining

- Post-processing