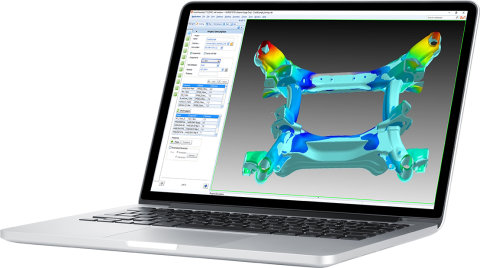

Visual-Weld & Assembly - Automotive Seam Welding

Be able to translate the welding fabrication process into a virtual model that can simulate this process and its heat effects. Understand the benefit of combining rapid distortion engineering and welding process validation to minimize engineering & response time. Understand requirements and values delivered of rapid distortion engineering for complex designs (get a first idea and provide a quick distortion response to designs, design changes, clamps, etc.), refinement of the engineering approach with localized process simulation, and necessary steps towards accurate process validation and accurate process validation of complex designs. Be able to go from geometry to mesh to a simulation model to assessing computed results and generate models that run stable, as fast as possible, still delivering accurate results.

Audience

Manufacturing engineering from design support to process validation, pre-series validation

Prerequisites

Basic Knowledge of CAD, CAE & Welding engineering. A video based basic training course will be provided ahead of the training.

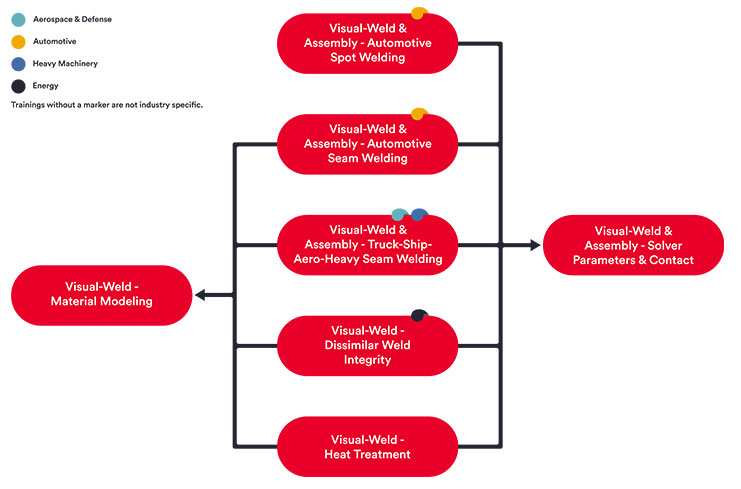

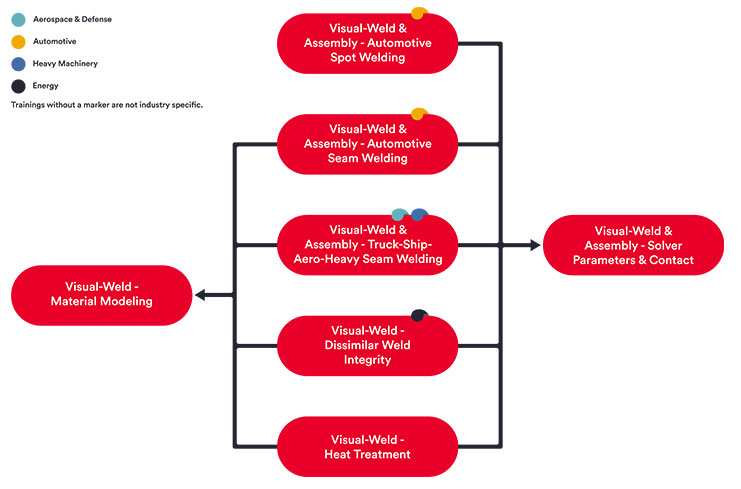

LEARNING PATH

SUGGESTED COURSES

概要

- Operate the graphic user interface of Visual Environment, focus welding

- Generate shell mid-surface-based models including weld beads to be used for rapid distortion engineering and process validation

- Generate localized solid models – and if required full solid models - to refine the engineering approach

- Best practices

- A focus can be put either on rapid distortion engineering or process validation

お探しのものが見つかりませんでしたか?

カスタマイズトレーニングを依頼

TRAINING PROGRAM

Day 1

- Concept of rapid distortion engineering and process validation, values to extract

- How to operate the Graphic User Interface & create own tailored toolbars

- How to go from a CAD model to a mid-surface mesh with weld beads

- How to generate 3D meshes for localized process validation models

- How to make sure meshes are good to go

Day 2

- Rapid distortion engineering

- Set-up and run a model for rapid distortion engineering

- Assess computed results

- Manage changes of design, clamping conditions, and weld sequence

- Localized process validation

- Set-up and run a localized model for process validation

- Understand the contents of a material database, manage material databases

- Manage heat input and process windows

- Manage changes of material for parts and wire, clamping conditions, and weld sequence

- Understand the influence of process parameters, clamping conditions and material on computed results

- Assess computed temperature, phase transformations, distortion, and residual stresses

- Mesh density, time stepping and precision – Best performance without compromising accuracy

- Full model process simulation

- Application to a representative large and complex model

Day 3

- Continuation of localized and large model welding process validation

- Industrial example