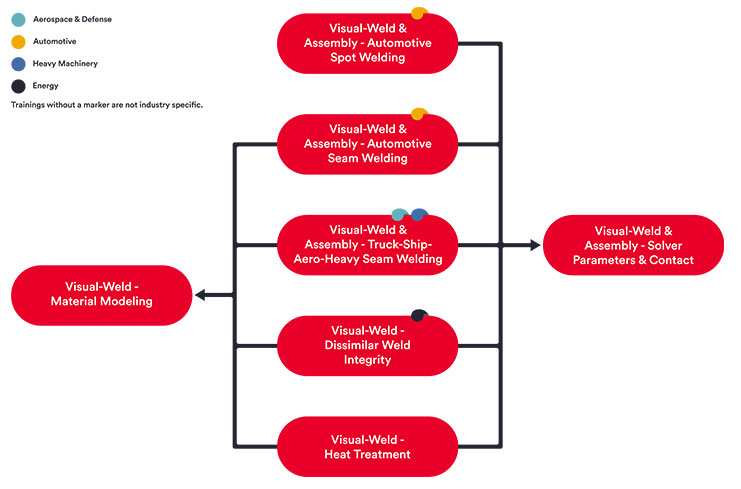

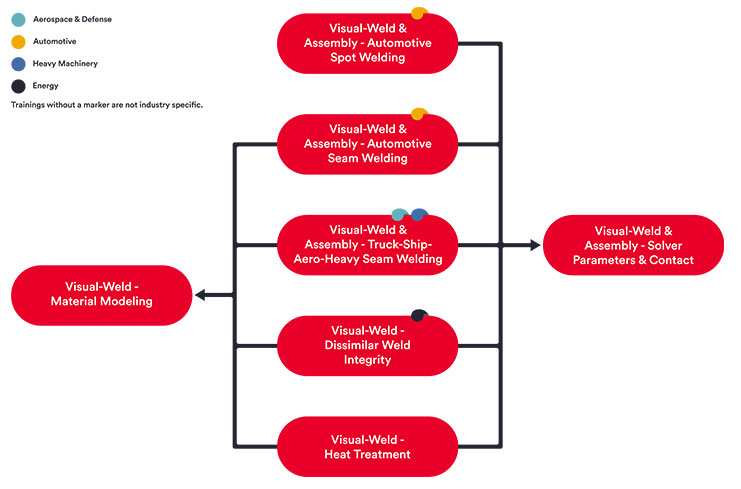

Visual-Weld - Material Modelling

Understand material phenomena important for the modelling of the heat effects of welding & heat treatment. Understand which material properties are important to model heat effects of welding & heat treatment. Understand how to model material so that it can be used in a welding of heat treatment simulation. Understand how to generate own material databases starting from a public database

Audience

Manufacturing engineering from design support to process validation.

Prerequisites

Completion of any basic training featuring Visual-Weld or Visual Heat Treatment.

LEARNING PATH

SUGGESTED COURSES

概要

This course focuses on advanced Visual-Weld & Heat Treatment solution usability. You will learn how to improve the fidelity of your simulation by improving your knowledge on material modeling, i.e. material phenomna, material properties, etc.

お探しのものが見つかりませんでしたか?

カスタマイズトレーニングを依頼

TRAINING PROGRAM

Day 1

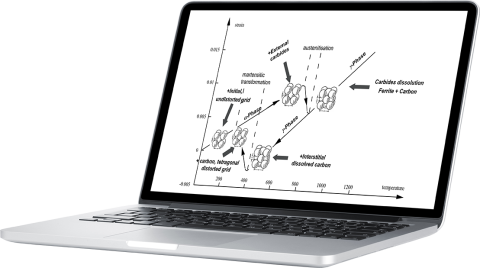

- Material phenomena in Welding & Heat Treatment

- Low alloyed carbon steel

- High alloyed steel / special metals

- 5000 / 6000 series aluminum alloys

- Ti-6Al-4V

- Modelling of Phase Transformations for Welding & Heat Treatment

- Material models and parameters to calibrate

- How to display ITT and CCT diagrams in Visual Environment

- Diffusion-controlled iso-thermal transformation

- Diffusion-controlled continuous cooling transformation

- Martensite transformation

- Tempering of Martensite transformation

- Transformation of not yet deposited material

- Thermal and mechanical modelling of the heat effects of welding and heat treatment including phase transformations

- Thermo-physical properties

- Mechanical properties

- Strain- and plasticity modelling

- S355 / A572 databases and variants