Visual-Weld & Assembly - Automotive Spot Welding

Be able to translate the welding assembly process into a virtual model that can simulate this process and its effects. Understand differences in simulation concepts to support design engineering, early manufacturing engineering, and pre-series evaluation in decision-making. Be able to manage virtually assembly, repeatability, and assembly with sub-assemblies. Work with nominal parts, part shapes as manufactured & scanned parts. Be able to go from geometry to mesh to a simulation model to assess computed results. Be able to generate models that run stable, as fast as possible, still delivering accurate results

Audience

Manufacturing engineering from design support to process validation, pre-series validation.

Prerequisites

Basic Knowledge of CAD, CAE & Welding Assembly engineering. A video based basic training course will be provided ahead of the training.

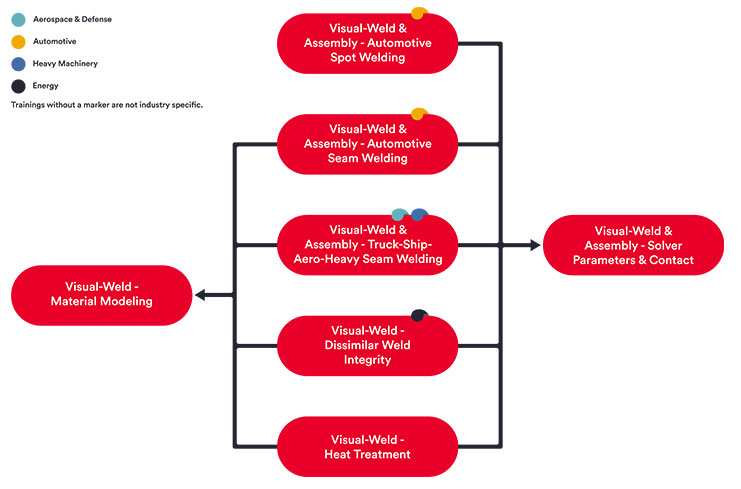

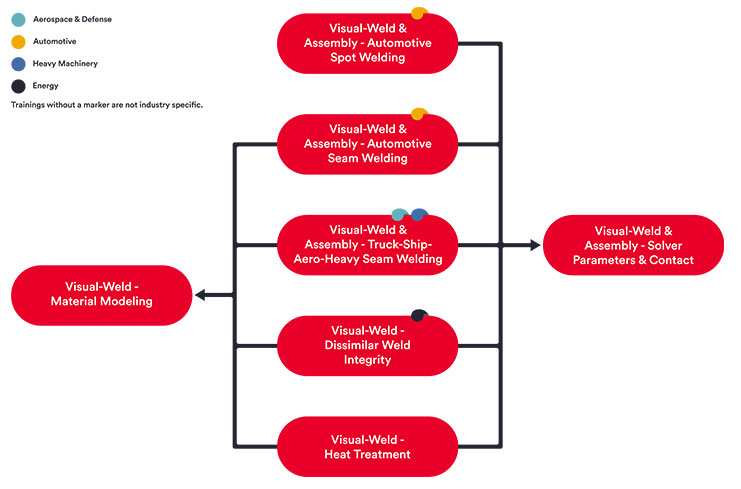

LEARNING PATH

SUGGESTED COURSES

概要

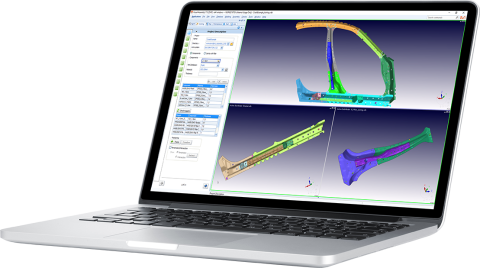

Operate the graphic user interface of Visual Environment, focus welding assembly. Generate shell mid-surface-based models of parts to be used for assembly process simulation. Understand best practices for Graphic user interface, Geometry to mesh, Material, Tools & pins, Spot welds – process definition, Clamping conditions, Contact, Solution parameters, Model check, Simulation runs, solution monitoring & file structure, Troubleshooting and Post-processing

お探しのものが見つかりませんでしたか?

カスタマイズトレーニングを依頼

TRAINING PROGRAM

Day 1

- Concept of Visual Assembly, values to extract

- How to operate the Graphic User Interface & create own tailored toolbars

- How to go from a CAD model to a mid-surface mesh

- How to extract tooling surfaces from fixtures

- How to generate tools (focus meshing)

- How to generate spot-welds and connectors (focus meshing)

- How to make sure all meshes are good to go

- How to exchange nominal parts with parts as manufactured or scanned parts

Day 2

- B-Pillar application with positioning and joining

- Set-up and run a model

- Assess computed results

- Manage changes of design, clamping conditions, and weld sequence

- Manage repeatability

- B-Pillar application with overlap resolve for rapid distortion engineering

- Mesh density, time stepping and precision – Best performance without compromising accuracy

- How to read spot-welds and product information from an Excel file

Day 3

- ESI trunk

- Techniques to use scan data (scan to mesh)

- How to manage supplier sub-assemblies & dealing with connectors

- Industrial example