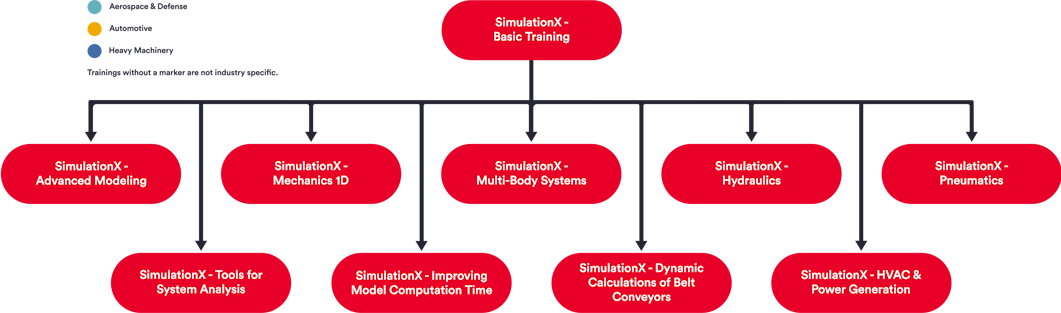

SimulationX - Pneumatics

In this training course, participants will learn how to build pneumatic components and systems. The fluid properties, as well as the different calculation options, are analyzed and explained. Creating own fluid models is demonstrated using the SimulationX Fluid Designer. The training demonstrates both the detailed modeling of subsystems and the creation of larger systems. The focus of this training is the correct handling of valve and cylinder models as part of the overall system. The user gains an insight into the calculation approaches used for pneumatic resistances. Furthermore, interactions between pneumatic components with mechanics as well as with thermal systems are explained. During the training, numerous practical examples are used for explanation.

Day 1

- Modelling and simulating pneumatic components and systems

- Concept and structure of the Pneumatic library

- Properties and use of model elements

- Description of fluid characteristics and pneumatic connections

- Pneumatic resistances

- Extent of the fluid catalogs, SimulationX Fluid Designer

- Valve models and cylinder drives

- Pneumatic-mechanical transformers overlap with mechanics

- Gas mixtures

- Overview of further fluid libraries, e.g., “HVAC and Power Generation (Basics),” “Heat Transfer” and “Vehicle Pneumatics.”

- Exercises:

- Pneumatic check valve

- Pneumatic cylinder

- Pneumatic damper actuator

- Compressed air treatment