- Home

- Resources

- Tips & Tricks

Tips & Tricks

e-café #5- Pilotage du refroidissement par thermocouple à l’aide de ProCAST™ et QuikCAST™

Pilotage du refroidissement par thermocouple à l’aide de ProCAST™ et QuikCAST™

Mathieu

Moerckel

Casting

e-café #2- Prédiction de la localisation des inclusions de sable à l’aide de ProCAST™

Prédiction de la localisation des inclusions de sable à l’aide de ProCAST™

Mathieu

Moerckel

Casting

e-café #1- Détermination de la courbe de déplacement du piston à l’aide de ProCAST™

Détermination de la courbe de déplacement du piston à l’aide de ProCAST™

Mathieu

Moerckel

Casting

Static comfort – Different encrypted data display

How to display encrypted occupant when other data are also encrypted in the model.

Virtual Seat

Static Comfort - Sensors Grid

Sensors Grid Definition improvement in Virtual Seat Solution v2015 (VE 11)

Cécile

Cabane

Virtual Seat

Trim Manufacturing – Trim Adviser

Trim Adviser improvement in Virtual Seat Solution v2015 (VE 11)

Cécile

Cabane

Virtual Seat

Using Region sources in CFD-VisCART

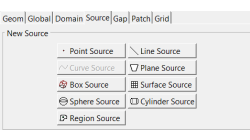

In order to control grid spacing at user-defined locations, mesh sources are a common tool in CFD-VisCART (Figure 1). Point, Line, Curve, Plane, Box and Surface sources have been available for several years. Cylinder and Sphere sources were introduced a few years back. To extend this tool set further, CFD-VisCART V2013.0 introduced Region sources.

Abraham

Meganathan

CFD

Automatic covering of larger unwanted holes in CFD-VisCART

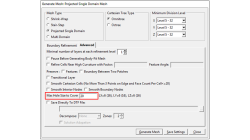

CFD-VisCART meshing automatically closes or covers holes in the geometry that are smaller in size than the cell size specified at the surfaces. To cover LARGER holes, the ‘Max Hole Size to Cover’ feature can be used. This feature, introduced in V2013.2, works to automatically cover larger holes in the geometry during mesh generation, and thus prevents the mesh from leaking into unwanted regions. This feature is available with all mesh types supported in CFD-VisCART.

Abraham

Meganathan

CFD

Process optimization: the future of numerical simulation software

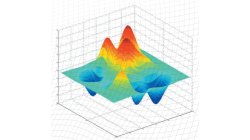

Optimization is becoming a very popular word. However, what does it mean and what does it involve? The goal of this e-tip is to give some keys about optimization concepts and its use in process optimization. In a first stage, we will describe the type of optimization problems that could be solved and in a second stage, the principles and algorithms will be presented. Finally, advantages and drawbacks of the different methods and algorithms will be addressed, with respect to the different types of optimization problems which can be solved.

Casting

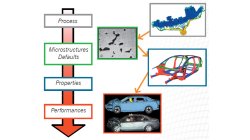

Casting simulation: from prototype to performance

Passenger safety in cars, planes and other transportation vehicles is an ethical obligation, a legal issue and a technological challenge. Simulation is a well implemented tool in order to test the behaviour of a car body during crash. The models, including rapid deformation and rupture, are sophisticated and reliable. Currently, most properties used in such simulations correspond to homogenous and defect free materials. However, cars are manufactured before being crashed. And manufacturing routes such as casting, but also stamping, forging or welding, do not provide defect free and homogeneous materials.

Casting