List of Training Courses

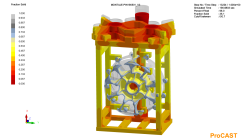

ProCAST - Investment Casting

Learn to use ProCAST to create the mesh and set-up for filling and solidification in the case of investment casting process.

Casting

CST-FO-B-PCIC

Basic

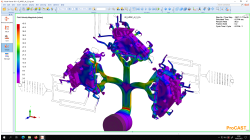

ProCAST - Die Casting

Learn to use ProCAST to create the mesh and set-up for cycling, filling, and solidification in the case of Die casting process.

Casting

CST-FO-B-PCDI

Basic

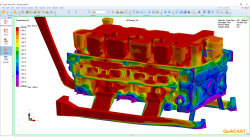

ProCAST - Sand Casting

Learn to use ProCAST to create the mesh and set-up for filling, and solidification in the case of Sand-Casting process.

Casting

CST-FO-B-PCSC

Basic

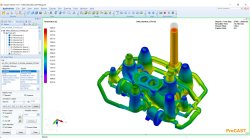

QuikCAST - Die Casting

Learn to use QuikCAST to create the mesh and set-up for cycling, filling, and solidification in the case of Die casting process.

Casting

CST-FO-B-QCDC

Basic

QuikCAST - Sand Casting

Learn to use QuikCAST to create the mesh and set-up for filling, and solidification in the case of Sand-Casting process.

Casting

CST-FO-B-QCSC

Basic

Casting Python for Visual-Environment

Apply python programming scripts unique to ESI software to enable automation and optimization of CAE Workflows. Utilize Python Libraries in both preprocessing, solving and postprocessing.

Casting

CST-FO-B-PVE

Basic

Casting Automation using Scripting in Visual-Environment

Develop efficient automation solutions to apply to your current challenges faced in your CAE workflows. Understand and apply the versatility and flexibility of Python scripting in Visual environment.

Casting

CST-FO-B-ASVE

Basic

Casting Automation using SDK-Batch

Learn how to leverage its command-line interface alongside the Python module VistaDb for streamlined task execution, optimizing efficiency in your workflows.

Casting

CST-FO-A-ASDK

Advanced

Casting Workflow Automation in Visual-Environment (Visual-SDK)

Gain expertise in scripting techniques to streamline workflows, implement parametric session executions, and craft efficient automation codes. Learn to develop customized GUIs with user friendly Visual SDK interface.

Casting

CST-FO-A-WFA

Basic

Casting Automation Hackathon

Gain expertise in scripting techniques to streamline workflows, implement session executions, and craft efficient automation codes. Enhance your CAE engineering productivity and unleash VE's full potential with our comprehensive training.

Casting

CST-FO-A-HACK

Advanced

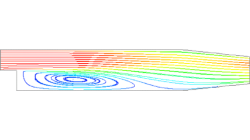

OpenFOAM - Foundation Training

Learn how to apply OpenFOAM to setup , run, and post-process CFD problems on small cases.

CFD

OF-FO-B-FT

Basic

OpenFOAM - Advanced Training

Learn how to use effectively OpenFOAM on real engineering problems and develop the toolbox to suite your needs. It covers general use and programming of OpenFOAM, building on topics presented earlier in the Foundation Course.

CFD

OF-FO-A-AT

Advanced

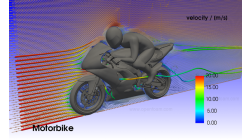

OpenFOAM - External Aerodynamics

Learn how to use effectively OpenFOAM to vehicle external aerodynamics simulation.

CFD

OF-FO-A-EQ

Advanced

OpenFOAM - Aeroacoustics (AAC)

Learn how to use effectively OpenFOAM to Aeroacoustics, Hydroacoustics and Hydro/Aero-Vibroacoustics simulations. Learn industrial best practices. Learn AAC theory and modeling options to improve your simulations accuracy, stability, and robustness.

CFD

OF-FO-A-AAC

Advanced

OpenFOAM - Fire Modeling

Learn how to use effectively OpenFOAM to fire safety applications for the design of buildings, car parks, tunnels and others..

CFD

OF-FO-A-FM

Advanced

OpenFOAM - Adjoint Optimisation

Learn how to use effectively the adjoint method in aerodynamic and hydrodynamic shape optimization using OpenFOAM

CFD

OF-FO-A-AO

Advanced

OpenFOAM - Overset

Learn how to use effectively overset (chimera) meshing in OpenFOAM in all engineering sectors, especially transportation: Automotive, Aerospace, Marine, Rail.

CFD

OF-FO-A-OS

Advanced

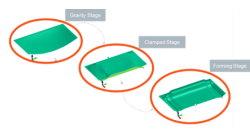

PAM-FORM - Composites Basic Training

Understand material models for dry textiles or prepregs. Be able to model, analyze results and optimize through simulation standard forming / thermoforming processes. Be able to identify required data and determine proper assumptions for simulations.

Composites

CMP-FO-B-COM

Basic

PAM-FORM - Plastics and Trims Basic Training

Be able to model, analyze results and optimize through simulation: Standard injection or infusion processes considering thermal effects including preheating and curing processes Be able to identify required data and to determine proper assumptions for simulations.

Composites

CMP-FO-B-PT

Basic

PAM-RTM - Basic Training

Be able to model, analyze results and optimize through simulation residual stresses and resulting geometrical distortions. Be able to identify required data and to determine proper assumptions for simulations.

Composites

CMP-FO-B-DIS

Basic