- Home

- Resources

- Tips & Tricks

Tips & Tricks

SEA - Virtual Transmission Loss

In a complex SEA model made out of several subsystems, using VA One is possible to extract the transmission loss (TL) of one or various subsystems in a single step. Transmission loss of partitions e.g. walls, floor, windows, enclosures have been studied theoretically and experimentally over many years. Partitions are often inhomogeneous, non-uniform, comprise combinations of different materials, have indeterminate boundary conditions and are subject to sound complex fields. Surprisingly the sound transmission behavior of many plane partitions is quite well represented by a simple model which ignores the boundaries. Sound transmission loss can be used to correlate the vibro-acoustic behavior of simple and/or complex systems.

Ricardo

Alvarez

Vibro-Acoustics

VA One - FE or SEA- How to map trim thickness for sound package representation

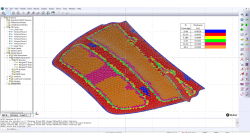

Sound control treatments / Trim ,(e.g. headliners,hood liners, dash panel and floor isolators, etc) have complex shapes with variable thickness, sometimes only CAD parts are available. How can I use this data to create noise control treatments (NCT) in FE and/or SEA models with variable thickness?. In this article it is shown how to create a variable thickness noise control treatment with VA One for SEA and/or FE purposes at the same time. A multiple noise control treatment (MNCT) is created for SEA purposes and multiple FE Faces with the mapped/discrete thicknesses are created for FE purposes,

Ricardo

Alvarez

Vibro-Acoustics

Find dominant path in SEA models

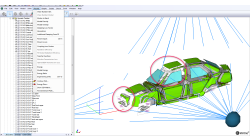

Statistical energy analysis (SEA) computes the flow of vibrational energy between coupled subsystems by applying principle of conservation of energy. Using conservation of energy power balance equations which govern response of a system. Since it is based on energy flow, path analysis is straight forward. In this article it is described how to extract the dominant path in a complex model using SEA and VA One . As a result the subsystems in the dominant path are displayed in the 3d window (All other subsystems are hidden).

Ricardo

Alvarez

Vibro-Acoustics

Weld Fatigue analysis based on the Dang Van Criteria

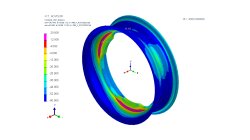

Numerical modeling of fatigue behavior has become critical for welding applications. For this purpose the ‘Dang Van criterion’ has been integrated in SYSWELD for fatigue evaluation of welded structure under multi-axial loadings. The Dang Van fatigue damage criterion is used to predict crack initiation and life duration of components subjected to damaging load. This criterion is based on multi-scale approach which assumes that shakedown occurs before crack initiation.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

Parallel processing

“To pull a bigger wagon, it is easier to add more horses than to grow a gigantic horse.” This paraphrased quotation nicely expresses the basic concept of parallel processing. The speed of sequential computers has been doubling every eighteen months, according to Moore’s law. However, at any given time, that speed is limited by the state of the art in integrated circuit design and manufacturing. To circumvent that limitation, it is possible to split a given computationally intensive task among multiple processors working simultaneously.

Bohus

Ulrych

Casting

The manufacturing of sand cores

The manufacturing of iron, steel and non-ferrous castings is achieved using a variety of casting process designs, and most of these involve the use of sand cores which form the internal shape of the casting. A good quality casting requires a good quality core. Dimensional stability, uniform density, strength, hardness and permeability are some of the characteristics that need to be controlled. A good core must have suffi cient strength and hardness to be handled and to resist during the pouring of liquid metal. Suffi cient permeability is also necessary for the escape of gases generated during the casting process. The diff erent manufacturing processes and some of the issues related to core production will be discussed here.

Casting

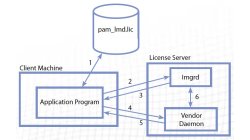

FLEXlm protection file system

ESI group needs to license, manage and track a variety of licensing options, platform and product dependencies. FLEXlm is one of the only software that is up to this task. A simple, shrinkwrapped license management product would not be powerful and flexible enough to license all ESI products.

Casting

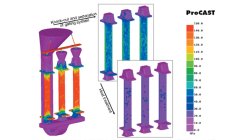

The challenge of simulating casting and heat treatment

Foundries that have implemented casting simulation to shorten development time, further wish to use simulation in order to reduce the cost of subsequent processing steps. This often requires the simulation of heat treatment.

Casting, Welding & Assembly

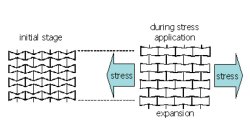

Why it is useful to describe problems in terms of non-dimensional parameters and which ones are the main important in solidification?

A dimensionless quantity is a quantity without any physical units. Such a number is typically defi ned as a product or ratio of quantities which do have units, in such a way that all units cancel. Dimensionless quantities are widely used in the fields of physics and engineering but also in every day life.

Casting