- Home

- Resources

- Tips & Tricks

Tips & Tricks

Using Region sources in CFD-VisCART

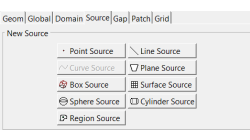

In order to control grid spacing at user-defined locations, mesh sources are a common tool in CFD-VisCART (Figure 1). Point, Line, Curve, Plane, Box and Surface sources have been available for several years. Cylinder and Sphere sources were introduced a few years back. To extend this tool set further, CFD-VisCART V2013.0 introduced Region sources.

Abraham

Meganathan

CFD

Automatic covering of larger unwanted holes in CFD-VisCART

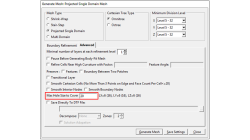

CFD-VisCART meshing automatically closes or covers holes in the geometry that are smaller in size than the cell size specified at the surfaces. To cover LARGER holes, the ‘Max Hole Size to Cover’ feature can be used. This feature, introduced in V2013.2, works to automatically cover larger holes in the geometry during mesh generation, and thus prevents the mesh from leaking into unwanted regions. This feature is available with all mesh types supported in CFD-VisCART.

Abraham

Meganathan

CFD

Model clipping feature in CFD-VisCART and CFD-GEOM

For better visualization of the geometry and mesh, a model clipping feature was introduced in CFD-VisCART and CFD-GEOM V2013.0. The following sections illustrate the usage and benefits of this feature.

Abraham

Meganathan

CFD

Improve Productivity Using Scripts [Video Format]

As simulations become more integrated with the design process, engineers often spend time on repeated operations that do not contribute to their productivity. There is a need for tools that could capture, preserve and transfer the knowledge within the organization or to its customers.

Abraham

Meganathan

CFD

Process optimization: the future of numerical simulation software

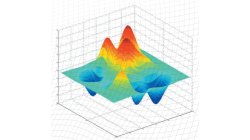

Optimization is becoming a very popular word. However, what does it mean and what does it involve? The goal of this e-tip is to give some keys about optimization concepts and its use in process optimization. In a first stage, we will describe the type of optimization problems that could be solved and in a second stage, the principles and algorithms will be presented. Finally, advantages and drawbacks of the different methods and algorithms will be addressed, with respect to the different types of optimization problems which can be solved.

Casting

Casting simulation: from prototype to performance

Passenger safety in cars, planes and other transportation vehicles is an ethical obligation, a legal issue and a technological challenge. Simulation is a well implemented tool in order to test the behaviour of a car body during crash. The models, including rapid deformation and rupture, are sophisticated and reliable. Currently, most properties used in such simulations correspond to homogenous and defect free materials. However, cars are manufactured before being crashed. And manufacturing routes such as casting, but also stamping, forging or welding, do not provide defect free and homogeneous materials.

Casting

Parallel processing

“To pull a bigger wagon, it is easier to add more horses than to grow a gigantic horse.” This paraphrased quotation nicely expresses the basic concept of parallel processing. The speed of sequential computers has been doubling every eighteen months, according to Moore’s law. However, at any given time, that speed is limited by the state of the art in integrated circuit design and manufacturing. To circumvent that limitation, it is possible to split a given computationally intensive task among multiple processors working simultaneously.

Bohus

Ulrych

Casting

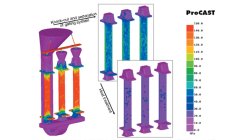

Critical issues in modelling investment casting

Reduce part development lead-times by a better knowledge of process and an early confi rmation of metallurgical capabilities is one of the main topics for investment casting technology. Numerical simulation is one of the major tools which can be used to face this goal. This e-tip illustrates a simulation methodology usable to optimize a casting design in an effi cient and rapid way.

Casting

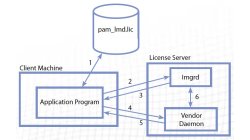

FLEXlm protection file system

ESI group needs to license, manage and track a variety of licensing options, platform and product dependencies. FLEXlm is one of the only software that is up to this task. A simple, shrinkwrapped license management product would not be powerful and flexible enough to license all ESI products.

Casting

The challenge of simulating casting and heat treatment

Foundries that have implemented casting simulation to shorten development time, further wish to use simulation in order to reduce the cost of subsequent processing steps. This often requires the simulation of heat treatment.

Casting, Welding & Assembly