- Home

- Resources

- Tips & Tricks

Tips & Tricks

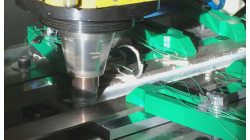

Friction Stir Welding modelling with an Axi-symmetric tool

Friction Stir Welding (FSW) is an innovative technology, which allows a solid junction of heterogeneous alloys, using a wear-resistant rotary tool that follows the welding seam. ESI Welding solution allows todays to predict temperature generated by FSW process. The proposed methodology is based on local approach that cannot give global distortion of the welded components. The aim of this article is to show how user can setup it own FSW process and run the computation using Visual Weld application

Mandikizinoyou

Taro

Virtual Manufacturing, Welding & Assembly

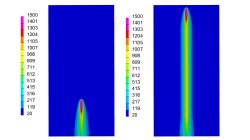

Welding simulation with FAST3D method in Visual Weld

A new method is described, which allows to reduce computation time significantly. It is used for transient simulations with moving heat source, mainly for long welds. Its advantage is that it does not require any additional manipulations with the model.

Vsevolod

Troyanov

Welding & Assembly

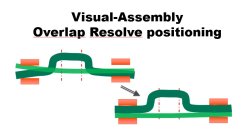

Visual-Assembly Overlap Resolve positioning

The most effective way how to position your distorted components into the clamping system.

Jan

Bejvl

Welding & Assembly, Virtual Integration Platform

e-café #3 - Customiser l'interface PAM-STAMP

Vous voulez personnaliser votre environnement de travail avec PAMSTAMP ? Cet e-café vous explique comment customiser l'interface en utilisant un workflow dédié et en utilisant des barres d'outils faites sur mesure.

Julien

Charbonneaux

Sheet Metal Forming

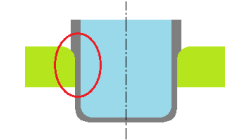

Recommendations to use IRONING option in PAM-STAMP

Several recommendations for ironing

Martin

Holecek

Sheet Metal Forming

e-Café #2 - Réaliser la compensation géométrique de l'outillage de façon automatique avec PAMSTAMP

Réaliser la compensation géométrique de l'outillage de façon automatique avec PAMSTAMP

Julien

Charbonneaux

Sheet Metal Forming

e-café #1 - Réaliser une mise en données en 5 minutes en utilisant le workflow PAMSTAMP

Presse simple effet avec PAMSTAMP

Julien

Charbonneaux

Sheet Metal Forming

Interface SYSWELD / ABAQUS

The objective of this interface is to perform a restart with ABAQUS using a SYSWELD computation. The difficulty is to transfer the metallurgical effects in a data structure which is not designed for it.

Yonggang

Duan

Welding & Assembly

How to Obtain Best Results within Reasonable Time from a Heat Treatment Simulation

Heat treated parts are in most cases not clamped during heat treatment, for an FEM analysis, at least a static determined clamping is needed that does not allow any rigid body motion.

Yonggang

Duan

Welding & Assembly

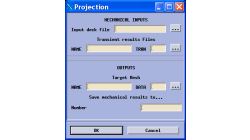

Stamping/HT Chaining of 3D Ring - Restart tool in Visual Heat Treatment

This article is to show effects of heat treatment on stresses when industrial mechanical parts are stamped (or welded) by 3 typical heat treatment steps: Heating, Quenching and Tempering. Tempering is generally considered effective in relieving stresses induced by quenching in addition to lowering hardness to within a specified range, or meeting certain mechanical property requirements.

Yonggang

Duan

Welding & Assembly