- Home

- Resources

- Tips & Tricks

Tips & Tricks

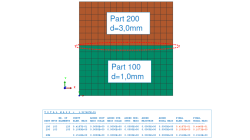

Why do total mass, sum of part masses and sum of nodal masses not match ?

This tip discusses the possible discrepancies in informations concerning total mass, part masses, nodal and element masses, given in the Virtual Performance Solution (VPS) output listing.

Jürgen

Rueckert

Virtual Performance

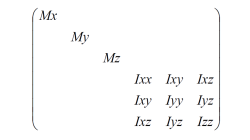

Which moments of inertia to use in added mass (MASS / ) cards ?

This tip discusses the choice of physically meaningful numbers to be used, when moments of inertia need to be specified in an added mass definition.

Jürgen

Rueckert

Virtual Performance

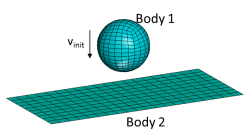

Some possible problems with CNTAC or TIED definitions

This tip discusses some of the reasons that might be responsible for problems with contact or tied definitions in a VPS simulation

Jürgen

Rueckert

Virtual Performance

Relation between Bulk Modulus K, Shear Modulus G, Young's Modulus E and Poisson's ratio ν

This tip explains the relations between the parameters that describe the linear elastic behavior of materials

Jürgen

Rueckert

Virtual Performance

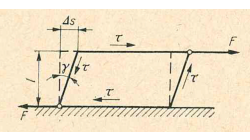

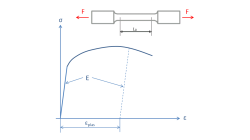

How to convert force-deflection into true stress-strain curves?

This tip helps to convert typical tensile test data into stress-strain curves to be used in many material models of Virtual Performance Solution (VPS)

Jürgen

Rueckert

Virtual Performance

Internal injection lines modeling

Internal injection lines on a shell model (i.e. made of internal element edges) are not supported by the parallel solver.

Mathilde

Chabin

Composites

Direct Opening of a mesh

The creation of a RTM project and loading of the model mesh is usually done in 2 steps.

Mathilde

Chabin

Composites

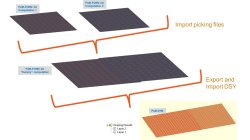

Coupling between PAM-FORM and PAM-RTM: multiple part mapping

Coupling between PAM-FORM 2G and PAM-RTM is done through a .DSY file. Thus, pre-forming process is simulated with PAM-FORM 2G and resulting fiber orientations that will affect permeabilities are transferred to PAM-RTM model setup.

Mathilde

Chabin

Composites

Parallel processing

“To pull a bigger wagon, it is easier to add more horses than to grow a gigantic horse.” This paraphrased quotation nicely expresses the basic concept of parallel processing. The speed of sequential computers has been doubling every eighteen months, according to Moore’s law. However, at any given time, that speed is limited by the state of the art in integrated circuit design and manufacturing. To circumvent that limitation, it is possible to split a given computationally intensive task among multiple processors working simultaneously.

Bohus

Ulrych

Casting

The manufacturing of sand cores

The manufacturing of iron, steel and non-ferrous castings is achieved using a variety of casting process designs, and most of these involve the use of sand cores which form the internal shape of the casting. A good quality casting requires a good quality core. Dimensional stability, uniform density, strength, hardness and permeability are some of the characteristics that need to be controlled. A good core must have suffi cient strength and hardness to be handled and to resist during the pouring of liquid metal. Suffi cient permeability is also necessary for the escape of gases generated during the casting process. The diff erent manufacturing processes and some of the issues related to core production will be discussed here.

Casting