- Home

- Resources

- Tips & Tricks

Tips & Tricks

Model clipping feature in CFD-VisCART and CFD-GEOM

For better visualization of the geometry and mesh, a model clipping feature was introduced in CFD-VisCART and CFD-GEOM V2013.0. The following sections illustrate the usage and benefits of this feature.

Abraham

Meganathan

CFD

Improve Productivity Using Scripts [Video Format]

As simulations become more integrated with the design process, engineers often spend time on repeated operations that do not contribute to their productivity. There is a need for tools that could capture, preserve and transfer the knowledge within the organization or to its customers.

Abraham

Meganathan

CFD

Weld Fatigue analysis based on the Dang Van Criteria

Numerical modeling of fatigue behavior has become critical for welding applications. For this purpose the ‘Dang Van criterion’ has been integrated in SYSWELD for fatigue evaluation of welded structure under multi-axial loadings. The Dang Van fatigue damage criterion is used to predict crack initiation and life duration of components subjected to damaging load. This criterion is based on multi-scale approach which assumes that shakedown occurs before crack initiation.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

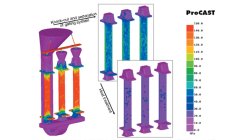

The challenge of simulating casting and heat treatment

Foundries that have implemented casting simulation to shorten development time, further wish to use simulation in order to reduce the cost of subsequent processing steps. This often requires the simulation of heat treatment.

Casting, Welding & Assembly

Boundary layer meshing with CFD-ACE+ [video format]

The accuracy of a CFD solution is strongly dependent on how well the mesh resolves geometry and flow features. This is especially true for near wall regions (boundary layer) where viscous forces are not negligible compared to inertial forces.

Abraham

Meganathan

CFD

How to check what software version you are running

There is a very fast and easy way to verify what software version you are running for your ESI CFD applications. You most likely know that this information is available for the GUI by clicking on 'Help → About ...', and for solvers by looking in the output file.

Abraham

Meganathan

CFD

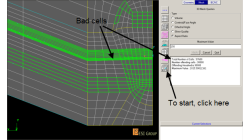

Always Make Sure You Have a Good Mesh Quality

The mesh has a great influence on the solver convergence and solution of every CFD Simulation. The user is strongly advised to check the quality of a numerical mesh.

Abraham

Meganathan

CFD

Copy/Paste Viewpoint tools

Usually, when performing a particular simulation, it is necessary to compare the results of similar models or the same model at different operating conditions. It is important that the two (or more) cases being compared be viewed from the same angle and at the same zoom level.

Abraham

Meganathan

CFD

Using "Visual Scaling" for Models with Drastically Varying Length Scales

For models that have drastically varying length scales, it can be difficult to create the grid, setup a model, and post-process the results. CFD-GEOM, CFD-ACE-GUI and CFD-VIEW have a "Visual Scale" capability that can significantly help when working with these types of models.

Abraham

Meganathan

CFD