- Home

- Resources

- Tips & Tricks

Tips & Tricks

Coupling between PAM-FORM and PAM-RTM: multiple part mapping

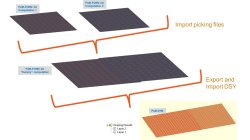

Coupling between PAM-FORM 2G and PAM-RTM is done through a .DSY file. Thus, pre-forming process is simulated with PAM-FORM 2G and resulting fiber orientations that will affect permeabilities are transferred to PAM-RTM model setup.

Mathilde

Chabin

Composites

Grouping option for CFD-VIEW Data Import

Grouping feature in CFD-ACE+ GUI and CFD-VIEW comes in handy when working with complex industrial models. This feature allows putting BC patches or VC entities into a group that can be manipulated easily, to either set up properties or display specific post-processing attributes.

Abraham

Meganathan

CFD

CFD-VIEW Scripting is easier than ever with Journaling

In addition to the numerous options and tools available via the CFD-VIEW user interface, the scripting capability of CFD-VIEW allows you to perform complex data processing on your simulation results, and gives you the option to run the post-processing phase of your simulation in batch mode.

Abraham

Meganathan

CFD

Weld Fatigue analysis based on the Dang Van Criteria

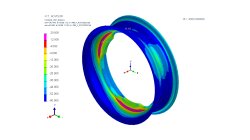

Numerical modeling of fatigue behavior has become critical for welding applications. For this purpose the ‘Dang Van criterion’ has been integrated in SYSWELD for fatigue evaluation of welded structure under multi-axial loadings. The Dang Van fatigue damage criterion is used to predict crack initiation and life duration of components subjected to damaging load. This criterion is based on multi-scale approach which assumes that shakedown occurs before crack initiation.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

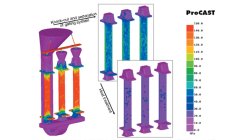

The challenge of simulating casting and heat treatment

Foundries that have implemented casting simulation to shorten development time, further wish to use simulation in order to reduce the cost of subsequent processing steps. This often requires the simulation of heat treatment.

Casting, Welding & Assembly

CFD-VIEW: Working with cell-center data in batch mode

Many improvements have been made in CFD-VIEW that allows the manipulation of cell-center data. The latest cell-center data additions implemented in CFD-VIEW V2011.0 include, for example, support for the MinMax Probe and the Calculator.

Abraham

Meganathan

CFD

"Per Pixel Lighting" display option in CFD-VIEW

When visualizing CFD solutions, it is often of interest to see a particular range of variable values, and it is therefore useful to be able to clip the surface coloring to that range, as to obtain a clearer view of the areas affected by the variable.

Abraham

Meganathan

CFD

Visualizing decomposed model without zonal interface outlines

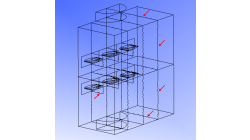

Running a simulation in parallel allows quicker turn around for larger and complex problems. Such parallel jobs require the computational domain to be decomposed into multiple zones. Such a multiple-zone file may be inconvenient to post-process in CFD-VIEW because zonal interface outlines will be visible and the original surfaces would have been split. As depicted in figure 1 below, these outlines can be numerous and may therefore hinder the clarity of the model.

Abraham

Meganathan

CFD

Visualizing particle size effect on Spray particle trajectory

When analyzing flow vectors, one can get a general trend of the direction of the flow and locations of recirculation. But what if you need to specifically know where a particle will end up? Maybe release points need to be studied. Then, the size and mass can make a difference in the path a particle travels.

Abraham

Meganathan

CFD