- Home

- Resources

- Tips & Tricks

Tips & Tricks

Heat Power display in Visual Weld

The aim of this development in Visual Weld 14.5 + Sysweld 2019.0 is to display the Power Density. Currently, this functionality is only available in the old SysWeld GUI. The new functionality "Heat Power Display" is available through the "Welding Utilities" menu of Visual Weld.

Yonggang

Duan

Welding & Assembly

Conversion Files .fdb in .erfh5 on Network Drive

It is not straightforward to do the conversion Files .fdb in .erfh5 on Network Drive in Visual Viewer. In order to make it work properly, it is necessary to map network drive to the local machine. In this way, the files on network could be handled like on local machine and the conversion from fdb to erf will be working properly.

Yonggang

Duan

Multiphysics, Welding & Assembly

Coupling windows for postreatment visualization

When comparison between results is needed, coupling windows and synchronizing animations is a key tool.

Sandrine

Dischert

Multiphysics, Welding & Assembly, Virtual Integration Platform

Boundary Layer Mesh tool demonstration

Easily creating a connection between a tetramesh and an hexamesh is possible, using Boundary Layer Mesh tool.

Sandrine

Dischert

Multiphysics, Welding & Assembly, Virtual Integration Platform

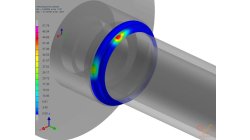

Heat Sources in Sysweld

From finite element point of view, a heat source is modelled in SYSWELD by a volume density of energy named Qr (W/mm3) applied to elements, which move along the welding trajectory.

Yonggang

Duan

Welding & Assembly

Static comfort – Different encrypted data display

How to display encrypted occupant when other data are also encrypted in the model.

Virtual Seat

Static Comfort - Sensors Grid

Sensors Grid Definition improvement in Virtual Seat Solution v2015 (VE 11)

Cécile

Cabane

Virtual Seat

Trim Manufacturing – Trim Adviser

Trim Adviser improvement in Virtual Seat Solution v2015 (VE 11)

Cécile

Cabane

Virtual Seat

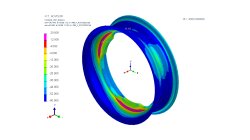

Weld Fatigue analysis based on the Dang Van Criteria

Numerical modeling of fatigue behavior has become critical for welding applications. For this purpose the ‘Dang Van criterion’ has been integrated in SYSWELD for fatigue evaluation of welded structure under multi-axial loadings. The Dang Van fatigue damage criterion is used to predict crack initiation and life duration of components subjected to damaging load. This criterion is based on multi-scale approach which assumes that shakedown occurs before crack initiation.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly