- Home

- Resources

- Tips & Tricks

Tips & Tricks

Boundary Layer Mesh tool demonstration

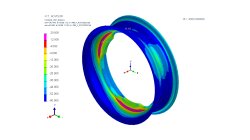

Easily creating a connection between a tetramesh and an hexamesh is possible, using Boundary Layer Mesh tool.

Sandrine

Dischert

Multiphysics, Welding & Assembly, Virtual Integration Platform

Heat Sources in Sysweld

From finite element point of view, a heat source is modelled in SYSWELD by a volume density of energy named Qr (W/mm3) applied to elements, which move along the welding trajectory.

Yonggang

Duan

Welding & Assembly

Using Region sources in CFD-VisCART

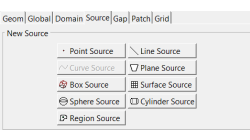

In order to control grid spacing at user-defined locations, mesh sources are a common tool in CFD-VisCART (Figure 1). Point, Line, Curve, Plane, Box and Surface sources have been available for several years. Cylinder and Sphere sources were introduced a few years back. To extend this tool set further, CFD-VisCART V2013.0 introduced Region sources.

Abraham

Meganathan

CFD

Automatic covering of larger unwanted holes in CFD-VisCART

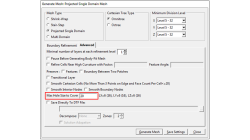

CFD-VisCART meshing automatically closes or covers holes in the geometry that are smaller in size than the cell size specified at the surfaces. To cover LARGER holes, the ‘Max Hole Size to Cover’ feature can be used. This feature, introduced in V2013.2, works to automatically cover larger holes in the geometry during mesh generation, and thus prevents the mesh from leaking into unwanted regions. This feature is available with all mesh types supported in CFD-VisCART.

Abraham

Meganathan

CFD

Weld Fatigue analysis based on the Dang Van Criteria

Numerical modeling of fatigue behavior has become critical for welding applications. For this purpose the ‘Dang Van criterion’ has been integrated in SYSWELD for fatigue evaluation of welded structure under multi-axial loadings. The Dang Van fatigue damage criterion is used to predict crack initiation and life duration of components subjected to damaging load. This criterion is based on multi-scale approach which assumes that shakedown occurs before crack initiation.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

Parallel processing

“To pull a bigger wagon, it is easier to add more horses than to grow a gigantic horse.” This paraphrased quotation nicely expresses the basic concept of parallel processing. The speed of sequential computers has been doubling every eighteen months, according to Moore’s law. However, at any given time, that speed is limited by the state of the art in integrated circuit design and manufacturing. To circumvent that limitation, it is possible to split a given computationally intensive task among multiple processors working simultaneously.

Bohus

Ulrych

Casting

The manufacturing of sand cores

The manufacturing of iron, steel and non-ferrous castings is achieved using a variety of casting process designs, and most of these involve the use of sand cores which form the internal shape of the casting. A good quality casting requires a good quality core. Dimensional stability, uniform density, strength, hardness and permeability are some of the characteristics that need to be controlled. A good core must have suffi cient strength and hardness to be handled and to resist during the pouring of liquid metal. Suffi cient permeability is also necessary for the escape of gases generated during the casting process. The diff erent manufacturing processes and some of the issues related to core production will be discussed here.

Casting

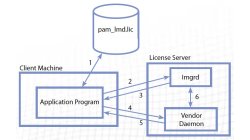

FLEXlm protection file system

ESI group needs to license, manage and track a variety of licensing options, platform and product dependencies. FLEXlm is one of the only software that is up to this task. A simple, shrinkwrapped license management product would not be powerful and flexible enough to license all ESI products.

Casting

The challenge of simulating casting and heat treatment

Foundries that have implemented casting simulation to shorten development time, further wish to use simulation in order to reduce the cost of subsequent processing steps. This often requires the simulation of heat treatment.

Casting, Welding & Assembly