- Home

- Resources

- Tips & Tricks

Tips & Tricks

How to manage small sized Reference Boxes?

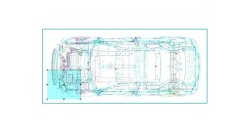

This paper is introducing the “–RB” option of the FD mesh generator allowing PAM-CEM/FD users to manage one limited part of a complete CAD model, without any hand-made cleaning stage

Jean-Claude

Kedzia

Electromagnetics

Physical Optics (PO) VS. Geometrical Optics (GO)

The purpose of this article is to compare two High Frequency formalisms, namely Physical Optics & Geometrical Optics, with a brief overview of their advantages & drawbacks.

Jean-Claude

Kedzia

Electromagnetics

How to avoid oscillatory phenomena with short circuited terminals of Cable Networks ?

Cable Networks with short-circuited terminals may exhibit Common-Mode (CM) currents with a highly oscillatory behavior. This article illustrates one solution to eliminate such behavior by considering lossy dielectric coatings varying with the frequency.

Jean-Claude

Kedzia

Electromagnetics

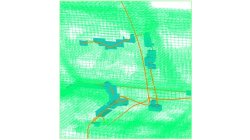

FD Interpolating Scheme near Metallic Structures

This article illustrates the PAM-CEM/FD interpolation scheme applied to compute the tangential electric field along wires’ path running near metallic structures (and aimed at avoiding the management of field components on both sides of the surface).

Jean-Claude

Kedzia

Electromagnetics

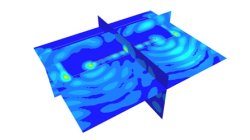

3D/Multiconductor Transmission Lines (MTL) Coupling VS. Stand-Alone FDTD (Accuracy)

This article is aimed at comparing the 3D/Multiconductor Transmission Lines (MTL) coupling accuracy with the PAM-CEM/FD stand-alone use, when applied to simplified wired models. Recommendations for good agreement are also proposed.

Jean-Claude

Kedzia

Electromagnetics

Process optimization: the future of numerical simulation software

Optimization is becoming a very popular word. However, what does it mean and what does it involve? The goal of this e-tip is to give some keys about optimization concepts and its use in process optimization. In a first stage, we will describe the type of optimization problems that could be solved and in a second stage, the principles and algorithms will be presented. Finally, advantages and drawbacks of the different methods and algorithms will be addressed, with respect to the different types of optimization problems which can be solved.

Casting

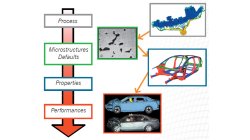

Casting simulation: from prototype to performance

Passenger safety in cars, planes and other transportation vehicles is an ethical obligation, a legal issue and a technological challenge. Simulation is a well implemented tool in order to test the behaviour of a car body during crash. The models, including rapid deformation and rupture, are sophisticated and reliable. Currently, most properties used in such simulations correspond to homogenous and defect free materials. However, cars are manufactured before being crashed. And manufacturing routes such as casting, but also stamping, forging or welding, do not provide defect free and homogeneous materials.

Casting

Parallel processing

“To pull a bigger wagon, it is easier to add more horses than to grow a gigantic horse.” This paraphrased quotation nicely expresses the basic concept of parallel processing. The speed of sequential computers has been doubling every eighteen months, according to Moore’s law. However, at any given time, that speed is limited by the state of the art in integrated circuit design and manufacturing. To circumvent that limitation, it is possible to split a given computationally intensive task among multiple processors working simultaneously.

Bohus

Ulrych

Casting

The manufacturing of sand cores

The manufacturing of iron, steel and non-ferrous castings is achieved using a variety of casting process designs, and most of these involve the use of sand cores which form the internal shape of the casting. A good quality casting requires a good quality core. Dimensional stability, uniform density, strength, hardness and permeability are some of the characteristics that need to be controlled. A good core must have suffi cient strength and hardness to be handled and to resist during the pouring of liquid metal. Suffi cient permeability is also necessary for the escape of gases generated during the casting process. The diff erent manufacturing processes and some of the issues related to core production will be discussed here.

Casting

Critical issues in modelling investment casting

Reduce part development lead-times by a better knowledge of process and an early confi rmation of metallurgical capabilities is one of the main topics for investment casting technology. Numerical simulation is one of the major tools which can be used to face this goal. This e-tip illustrates a simulation methodology usable to optimize a casting design in an effi cient and rapid way.

Casting