- Home

- Resources

- Tips & Tricks

Tips & Tricks

Parallel processing

“To pull a bigger wagon, it is easier to add more horses than to grow a gigantic horse.” This paraphrased quotation nicely expresses the basic concept of parallel processing. The speed of sequential computers has been doubling every eighteen months, according to Moore’s law. However, at any given time, that speed is limited by the state of the art in integrated circuit design and manufacturing. To circumvent that limitation, it is possible to split a given computationally intensive task among multiple processors working simultaneously.

Bohus

Ulrych

Casting

The manufacturing of sand cores

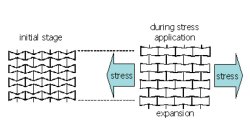

The manufacturing of iron, steel and non-ferrous castings is achieved using a variety of casting process designs, and most of these involve the use of sand cores which form the internal shape of the casting. A good quality casting requires a good quality core. Dimensional stability, uniform density, strength, hardness and permeability are some of the characteristics that need to be controlled. A good core must have suffi cient strength and hardness to be handled and to resist during the pouring of liquid metal. Suffi cient permeability is also necessary for the escape of gases generated during the casting process. The diff erent manufacturing processes and some of the issues related to core production will be discussed here.

Casting

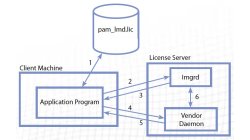

FLEXlm protection file system

ESI group needs to license, manage and track a variety of licensing options, platform and product dependencies. FLEXlm is one of the only software that is up to this task. A simple, shrinkwrapped license management product would not be powerful and flexible enough to license all ESI products.

Casting

Why it is useful to describe problems in terms of non-dimensional parameters and which ones are the main important in solidification?

A dimensionless quantity is a quantity without any physical units. Such a number is typically defi ned as a product or ratio of quantities which do have units, in such a way that all units cancel. Dimensionless quantities are widely used in the fields of physics and engineering but also in every day life.

Casting

Make an independent setup from existing pre and rst files in PAM-STAMP

Sometimes only rst files there are available and dependent pre file of an intermediate stage setup (lost data, picking with a process variant, …), which is not possible to run in another PAM-STAMP version, usually in newer version. It is possible to create a pre file independent on preceding rst files.

Tomas

Nosek

Sheet Metal Forming

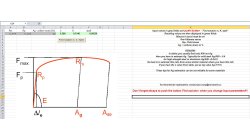

Determination of Krupkowsky parameters for hardening curve

In case there are no measured material data for simulation purposes, it is possible to determine hardening curve from information usually provided by material supplier.

Tomas

Nosek

Sheet Metal Forming

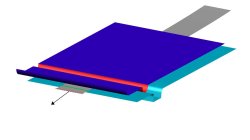

How to import a PAM-STAMP result into CATIA V5 with VRML export format ?

For a comparison of the virtual stamped part and the nominal CATIA V5 part one can use PAM-STAMP, or go back to CATIA. Since the meshed part is not easily converted into surfaces again, one solution is to use an overlay of the CAD part and of a VRML export of the stamp part.

Matthias

Schroeder

Sheet Metal Forming

How to encrypt material data sets in PAM-STAMP?

Major automotive companies spend a lot of money to describe all materials used in their simulation processes. To ensure simulation quality also at supplier sites, they want to give the material data sets to them, but not for free. One half of the solution is material encryption, the other a predefined expiration date.

Matthias

Schroeder

Sheet Metal Forming

Small collection of 3D meshed symbols for illustration purposes

During a project the need to visualize the functionality in 3D arose and some 3D symbols were created, which are now made available as a goody.

Matthias

Schroeder

Sheet Metal Forming

How to find out what forces are working inside the sheet or tube section ?

If you need insight on the restraining force of a geometrical drawbead or want to know the transmitted force in a sheet or tube section, you can define a force gauge.

Matthias

Schroeder

Sheet Metal Forming