- Home

- Resources

- Tips & Tricks

Tips & Tricks

Why is it important to have coupled stress calculations?

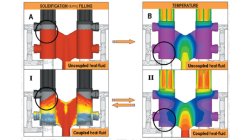

Casting process issues related to hot tearing and cracking of the casting, thermal fatigue of dies and prediction of the final shape of a part are a challenge for foundries. Powerful, multi-physics simulation tools are now available to address them. This e-tip will consider the advantages of a fully coupled thermal, fluid flow and stress analysis of casting, in particular in view of the above mentioned challenges.

Casting

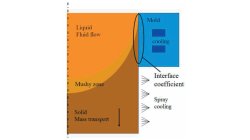

Thermomechanical modelling of continuous casting

Two application examples are showing new possibilities to take into account stress and deformation by the simulation of continuous casting processes. The variability of the presented examples prove that the proposed method is not limited to a certain class of applications, dimension and alloy composition. Since the gap formation can now be taken into account, the results are expected to be much more precise. This approach opens a wide field of application in order to better understand and control the heat transport in continuous casting processes.

Bohus

Ulrych

Casting

Modeling the solidification of cast irons

Successfully modeling solidification of Cast Iron is of great help for the foundries to reduce their production costs and thus to increase their profits. If the basic physical solidification phenomena are correctly modeled by the simulation tools mold risering can really be optimized.

Casting

Why it is useful to describe problems in terms of non-dimensional parameters and which ones are the main important in solidification?

A dimensionless quantity is a quantity without any physical units. Such a number is typically defi ned as a product or ratio of quantities which do have units, in such a way that all units cancel. Dimensionless quantities are widely used in the fields of physics and engineering but also in every day life.

Casting

Make an independent setup from existing pre and rst files in PAM-STAMP

Sometimes only rst files there are available and dependent pre file of an intermediate stage setup (lost data, picking with a process variant, …), which is not possible to run in another PAM-STAMP version, usually in newer version. It is possible to create a pre file independent on preceding rst files.

Tomas

Nosek

Sheet Metal Forming

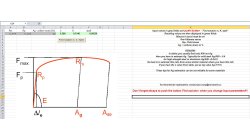

Determination of Krupkowsky parameters for hardening curve

In case there are no measured material data for simulation purposes, it is possible to determine hardening curve from information usually provided by material supplier.

Tomas

Nosek

Sheet Metal Forming

Influences of Solidification Length and Pressure Intensification on Gas Shrinkage Microporosity in Casting Components

Porosity in castings is a major defect since it affects the mechanical properties. In particular porosities are sites for the initiation of fatigue cracks. Therefore, the reduction of porosity fraction and size, the control of porosity distribution and morphology are crucial for the optimization of mechanical resistance of as cast components.

Casting

How to import a PAM-STAMP result into CATIA V5 with VRML export format ?

For a comparison of the virtual stamped part and the nominal CATIA V5 part one can use PAM-STAMP, or go back to CATIA. Since the meshed part is not easily converted into surfaces again, one solution is to use an overlay of the CAD part and of a VRML export of the stamp part.

Matthias

Schroeder

Sheet Metal Forming

How to encrypt material data sets in PAM-STAMP?

Major automotive companies spend a lot of money to describe all materials used in their simulation processes. To ensure simulation quality also at supplier sites, they want to give the material data sets to them, but not for free. One half of the solution is material encryption, the other a predefined expiration date.

Matthias

Schroeder

Sheet Metal Forming

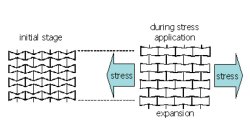

Small collection of 3D meshed symbols for illustration purposes

During a project the need to visualize the functionality in 3D arose and some 3D symbols were created, which are now made available as a goody.

Matthias

Schroeder

Sheet Metal Forming