- Home

- Resources

- Tips & Tricks

Tips & Tricks

Modeling the solidification of cast irons

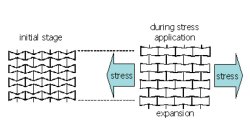

Successfully modeling solidification of Cast Iron is of great help for the foundries to reduce their production costs and thus to increase their profits. If the basic physical solidification phenomena are correctly modeled by the simulation tools mold risering can really be optimized.

Casting

Why it is useful to describe problems in terms of non-dimensional parameters and which ones are the main important in solidification?

A dimensionless quantity is a quantity without any physical units. Such a number is typically defi ned as a product or ratio of quantities which do have units, in such a way that all units cancel. Dimensionless quantities are widely used in the fields of physics and engineering but also in every day life.

Casting

Influences of Solidification Length and Pressure Intensification on Gas Shrinkage Microporosity in Casting Components

Porosity in castings is a major defect since it affects the mechanical properties. In particular porosities are sites for the initiation of fatigue cracks. Therefore, the reduction of porosity fraction and size, the control of porosity distribution and morphology are crucial for the optimization of mechanical resistance of as cast components.

Casting

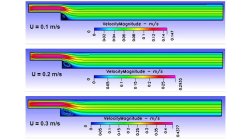

Boundary layer meshing with CFD-ACE+ [video format]

The accuracy of a CFD solution is strongly dependent on how well the mesh resolves geometry and flow features. This is especially true for near wall regions (boundary layer) where viscous forces are not negligible compared to inertial forces.

Abraham

Meganathan

CFD

How to check what software version you are running

There is a very fast and easy way to verify what software version you are running for your ESI CFD applications. You most likely know that this information is available for the GUI by clicking on 'Help → About ...', and for solvers by looking in the output file.

Abraham

Meganathan

CFD

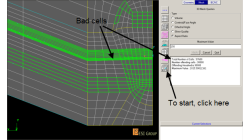

Always Make Sure You Have a Good Mesh Quality

The mesh has a great influence on the solver convergence and solution of every CFD Simulation. The user is strongly advised to check the quality of a numerical mesh.

Abraham

Meganathan

CFD

Copy/Paste Viewpoint tools

Usually, when performing a particular simulation, it is necessary to compare the results of similar models or the same model at different operating conditions. It is important that the two (or more) cases being compared be viewed from the same angle and at the same zoom level.

Abraham

Meganathan

CFD

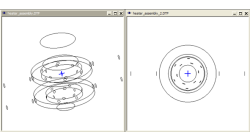

Using "Visual Scaling" for Models with Drastically Varying Length Scales

For models that have drastically varying length scales, it can be difficult to create the grid, setup a model, and post-process the results. CFD-GEOM, CFD-ACE-GUI and CFD-VIEW have a "Visual Scale" capability that can significantly help when working with these types of models.

Abraham

Meganathan

CFD

Parametric Studies Using SimManager

Parametric studies are an important aspect of CFD analysis. Parametric studies are used to perform trend base analyses, optimize the deign of a device, and/or to study the affect of different parameters on a process (What if? type analysis).

Abraham

Meganathan

CFD

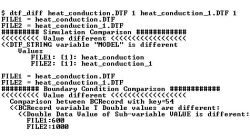

How to Compare the Model Setup Between Two DTF Files

Have you ever wanted to find the differences between two DTF files? If you have, then you will probably be interested in a DTF utility included in your ESI Software installation. The utility is called dtf_diff and can be found in your UTILS_2009.0/bin directory.

Abraham

Meganathan

CFD