- Home

- Resources

- Tips & Tricks

Tips & Tricks

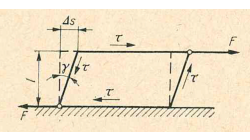

Preloading BOLTS

This tip provides methodology to pre stress elements in Virtual Performance Solution (VPS) to model Bolt assemblies.

Jean-Christophe

Allain

Virtual Performance

Hints on the usage of linear Tetrahedron (TETR4 / ) elements

This tip provides some background information on the question, when, or when not, to use the linear tetrahedron (TETR4 / ) element in Virtual Performance Solution (VPS)

Jürgen

Rueckert

Virtual Performance

Why do total mass, sum of part masses and sum of nodal masses not match ?

This tip discusses the possible discrepancies in informations concerning total mass, part masses, nodal and element masses, given in the Virtual Performance Solution (VPS) output listing.

Jürgen

Rueckert

Virtual Performance

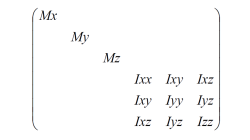

Which moments of inertia to use in added mass (MASS / ) cards ?

This tip discusses the choice of physically meaningful numbers to be used, when moments of inertia need to be specified in an added mass definition.

Jürgen

Rueckert

Virtual Performance

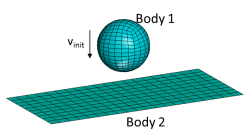

Some possible problems with CNTAC or TIED definitions

This tip discusses some of the reasons that might be responsible for problems with contact or tied definitions in a VPS simulation

Jürgen

Rueckert

Virtual Performance

Relation between Bulk Modulus K, Shear Modulus G, Young's Modulus E and Poisson's ratio ν

This tip explains the relations between the parameters that describe the linear elastic behavior of materials

Jürgen

Rueckert

Virtual Performance

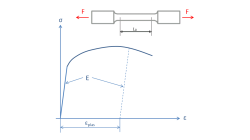

How to convert force-deflection into true stress-strain curves?

This tip helps to convert typical tensile test data into stress-strain curves to be used in many material models of Virtual Performance Solution (VPS)

Jürgen

Rueckert

Virtual Performance

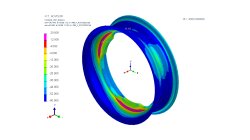

Weld Fatigue analysis based on the Dang Van Criteria

Numerical modeling of fatigue behavior has become critical for welding applications. For this purpose the ‘Dang Van criterion’ has been integrated in SYSWELD for fatigue evaluation of welded structure under multi-axial loadings. The Dang Van fatigue damage criterion is used to predict crack initiation and life duration of components subjected to damaging load. This criterion is based on multi-scale approach which assumes that shakedown occurs before crack initiation.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

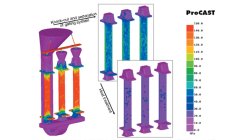

The challenge of simulating casting and heat treatment

Foundries that have implemented casting simulation to shorten development time, further wish to use simulation in order to reduce the cost of subsequent processing steps. This often requires the simulation of heat treatment.

Casting, Welding & Assembly