- Home

- Resources

- Tips & Tricks

Tips & Tricks

How to simulate welding process with variable weld speed and Heat power ?

In real process, the user changes the velocity depending to the distance already covered or still to cover in welding process. To better reproduce the start and the end of a welding process, the velocity must be able to vary during at least these two phases as well as the heat source power. And to be more generic, this feature introduces a time dependency of the heat source velocity and its power density.

Mandikizinoyou

Taro

Welding & Assembly, Virtual Performance, Virtual Integration Platform

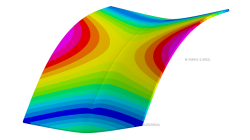

Horse saddle distortion modelling in Visual Weld

Welding of structures involves complex interactions between thermal, metallurgical and mechanical phenomena leading to residual stresses and distortions, which play a major role during subsequent service of these structures. Controlling material characteristics, residual stress and keep distortion within tolerances via the computer can significantly enhance the performance, the quality of the product and the structure’s service life

Mandikizinoyou

Taro

Sheet Metal Forming, Virtual Manufacturing, Multiphysics, Welding & Assembly

Restart Sysweld thermo-metallurgy and mechanical calculation in batch mode

The aim of this article consists to show sysweld/systus users how to perform a restart computation when a calculation run in batch mode is stopped in middle for some reasons or not.

Mandikizinoyou

Taro

Virtual Manufacturing, Multiphysics, Welding & Assembly

Overview of CSM Welding Advisor in Visual Environment 18.0.2

This tip is to give an overview of new CSM welding advisor in Visual Environment 18.0.2. This new advisor comes in replacement of Visual Welding advisor and uses Assembly solver to perform transient welding simulation.

Mandikizinoyou

Taro

Sheet Metal Forming, Virtual Manufacturing, Welding & Assembly

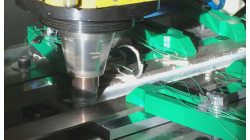

Friction Stir Welding modelling with an Axi-symmetric tool

Friction Stir Welding (FSW) is an innovative technology, which allows a solid junction of heterogeneous alloys, using a wear-resistant rotary tool that follows the welding seam. ESI Welding solution allows todays to predict temperature generated by FSW process. The proposed methodology is based on local approach that cannot give global distortion of the welded components. The aim of this article is to show how user can setup it own FSW process and run the computation using Visual Weld application

Mandikizinoyou

Taro

Virtual Manufacturing, Welding & Assembly

e-Café #2 PYFUN, PYSTOP - Programmer ses propres critères d'arrêt de calcul

Comment programmer des critères d'arrêt de calcul en Python

Jean-Charles

Paulin

Virtual Performance

e-Café #1- Construire sa propre carte matière MMAT à l’aide de Visual-Crash PAM

Construire sa propre carte matière MMAT à l’aide de Visual-Crash PAM

Maximilien

Jouy

Virtual Performance

How do I create an SEA cavity using shrinkwrap?

How to create FE acoustic cavities with complex shapes

Ricardo

Alvarez

CFD, Vibro-Acoustics

CFD-VIEW Colormap Options: Static, Dynamic, and Cumulative

The Colormap Settings panel in CFD-VIEW assigns colors to data sets. Identical data values on an object are displayed with the same color if they are using the same colormap display. Three options offer the user the opportunity to select the mode for updating the colormap as the underlying data changes, for example during transient simulations. These options are: Static, Dynamic, and Cumulative

Santosh

Kini

CFD

Auto Empty Folders option in CFD-GEOM

When importing large models into CFD-GEOM, you may notice that certain entities listed in the Model Manager may have a red box around them.

Abraham

Meganathan

CFD