- Home

- Resources

- Tips & Tricks

Tips & Tricks

e-café #3- Modélisation des opérations de poteyage et soufflage à l’aide Quik CAST™

Modélisation des opérations de poteyage et soufflage à l’aide Quik CAST™

Mathieu

Moerckel

Casting

e-café #2- Prédiction de la localisation des inclusions de sable à l’aide de ProCAST™

Prédiction de la localisation des inclusions de sable à l’aide de ProCAST™

Mathieu

Moerckel

Casting

e-café #1- Détermination de la courbe de déplacement du piston à l’aide de ProCAST™

Détermination de la courbe de déplacement du piston à l’aide de ProCAST™

Mathieu

Moerckel

Casting

Internal injection lines modeling

Internal injection lines on a shell model (i.e. made of internal element edges) are not supported by the parallel solver.

Mathilde

Chabin

Composites

Direct Opening of a mesh

The creation of a RTM project and loading of the model mesh is usually done in 2 steps.

Mathilde

Chabin

Composites

Fiber volume content contour

Two dedicated composites contours are available in PAM-FORM 2G post-processing: Shear angle and fiber directions.

Mathilde

Chabin

Composites

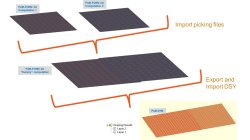

Coupling between PAM-FORM and PAM-RTM: multiple part mapping

Coupling between PAM-FORM 2G and PAM-RTM is done through a .DSY file. Thus, pre-forming process is simulated with PAM-FORM 2G and resulting fiber orientations that will affect permeabilities are transferred to PAM-RTM model setup.

Mathilde

Chabin

Composites

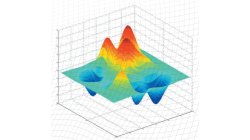

Process optimization: the future of numerical simulation software

Optimization is becoming a very popular word. However, what does it mean and what does it involve? The goal of this e-tip is to give some keys about optimization concepts and its use in process optimization. In a first stage, we will describe the type of optimization problems that could be solved and in a second stage, the principles and algorithms will be presented. Finally, advantages and drawbacks of the different methods and algorithms will be addressed, with respect to the different types of optimization problems which can be solved.

Casting

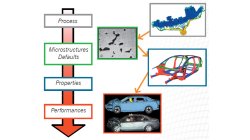

Casting simulation: from prototype to performance

Passenger safety in cars, planes and other transportation vehicles is an ethical obligation, a legal issue and a technological challenge. Simulation is a well implemented tool in order to test the behaviour of a car body during crash. The models, including rapid deformation and rupture, are sophisticated and reliable. Currently, most properties used in such simulations correspond to homogenous and defect free materials. However, cars are manufactured before being crashed. And manufacturing routes such as casting, but also stamping, forging or welding, do not provide defect free and homogeneous materials.

Casting

Parallel processing

“To pull a bigger wagon, it is easier to add more horses than to grow a gigantic horse.” This paraphrased quotation nicely expresses the basic concept of parallel processing. The speed of sequential computers has been doubling every eighteen months, according to Moore’s law. However, at any given time, that speed is limited by the state of the art in integrated circuit design and manufacturing. To circumvent that limitation, it is possible to split a given computationally intensive task among multiple processors working simultaneously.

Bohus

Ulrych

Casting