- Home

- Resources

- Tips & Tricks

Tips & Tricks

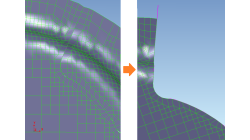

Improve trimming with Overshoot

Trimming in PAM-STAMP can fail due to a too short trimming segment curve leading to not cut properly the blank mesh. This can be solved by using Overshoot option in PAM-DIEMAKER for CATIA V5.

Matthias

Hoss

Sheet Metal Forming

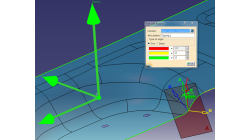

Trim and Shear Angles

Explanations about Trim and Shear Angles

Matthias

Hoss

Sheet Metal Forming

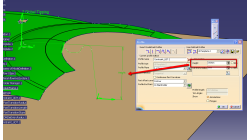

How to define height of constraint UDT profile with respect to the Blankholder?

Method to constrain the height of UDT profile bulge with respect to the Blankholder

Sureshbabu

Yalavarthi

Sheet Metal Forming

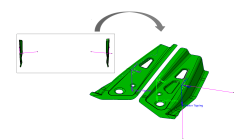

How to define tipping for free double parts with existing forming direction?

Recommendation to position properly the free double parts in case the forming direction is predefined.

Jana

Maradova

Sheet Metal Forming

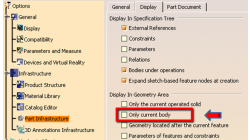

How to get back the hidden Part Definition after accepting dialogue?

Option to deactivate to get back the hidden part definition after accepting dialogue.

Sureshbabu

Yalavarthi

Sheet Metal Forming

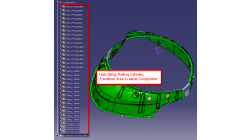

How to improve the update performance on iterations?

Recommendation to optimize the update performance during iterations.

Sureshbabu

Yalavarthi

Sheet Metal Forming

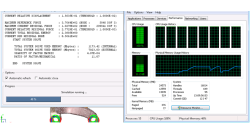

How to report and talk about simulation time in an objective manner

Reporting or talking about simulation time is a difficult subject. In the article a way to manage this problem in an objective manner is given.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

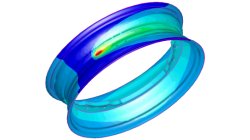

The transient method – the third out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The third one – the transient method – is used when not only distortion but also residual stresses and microstructure need to be evaluated. The part size allows running a heat source gradually. Compare it with a formability evaluation in sheet metal forming. A motorcycle rim may serve as an example.

Harald

Porzner

Welding & Assembly

The instantaneous method – the second out of three methods to simulate the heat effects of welding

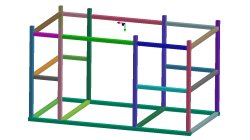

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The second one – the instantaneous method – is used when not only distortion but also residual stresses and micro-structure needs to be evaluated, but welded designs are so huge that it would make no more sense to use a classic transient method with a moving heat source – the simulation time would be too long. Compare it with a feasibility evaluation in sheet metal forming. A frame as produced in machine building, with more than 100 welds, may serve as an example.

Harald

Porzner

Welding & Assembly