- Home

- Resources

- Tips & Tricks

- The transient method – the third out of three methods to simulate the heat effects of welding

The transient method – the third out of three methods to simulate the heat effects of welding

To view the full version of this page (or to download files), please log in or create a new account

Weld Planner

Welding & Assembly

by Harald Porzner

|5 December 2012 | ESI

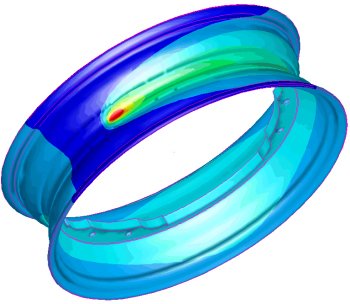

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The third one – the transient method – is used when not only distortion but also residual stresses and microstructure need to be evaluated. The part size allows running a heat source gradually. Compare it with a formability evaluation in sheet metal forming. A motorcycle rim may serve as an example.