- Home

- Resources

- Tips & Tricks

Tips & Tricks

How to call a script within a script

When using VA One developer's kit and new scripts are being created it is useful to call a script within a script. Here we show you how to achieve this.

Ricardo

Alvarez

Vibro-Acoustics

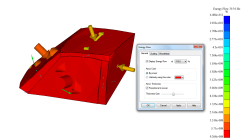

SEA - Display energy flow for a subsystem in complex models

In a complex SEA model made out of several subsystems, VA One can be used to display the energy flow to a particular subsystem in a couple of steps, this helps to understand how the energy flows to a receiving subsystem in order to define noise control strategies. One of the steps is to isolate the junctions associated to this subsystem, this will also help to understand / verify the connectivity of the model.

Ricardo

Alvarez

Vibro-Acoustics

SEA - Virtual Transmission Loss

In a complex SEA model made out of several subsystems, using VA One is possible to extract the transmission loss (TL) of one or various subsystems in a single step. Transmission loss of partitions e.g. walls, floor, windows, enclosures have been studied theoretically and experimentally over many years. Partitions are often inhomogeneous, non-uniform, comprise combinations of different materials, have indeterminate boundary conditions and are subject to sound complex fields. Surprisingly the sound transmission behavior of many plane partitions is quite well represented by a simple model which ignores the boundaries. Sound transmission loss can be used to correlate the vibro-acoustic behavior of simple and/or complex systems.

Ricardo

Alvarez

Vibro-Acoustics

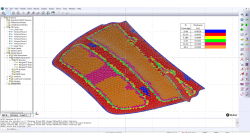

VA One - FE or SEA- How to map trim thickness for sound package representation

Sound control treatments / Trim ,(e.g. headliners,hood liners, dash panel and floor isolators, etc) have complex shapes with variable thickness, sometimes only CAD parts are available. How can I use this data to create noise control treatments (NCT) in FE and/or SEA models with variable thickness?. In this article it is shown how to create a variable thickness noise control treatment with VA One for SEA and/or FE purposes at the same time. A multiple noise control treatment (MNCT) is created for SEA purposes and multiple FE Faces with the mapped/discrete thicknesses are created for FE purposes,

Ricardo

Alvarez

Vibro-Acoustics

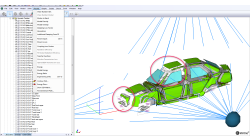

Find dominant path in SEA models

Statistical energy analysis (SEA) computes the flow of vibrational energy between coupled subsystems by applying principle of conservation of energy. Using conservation of energy power balance equations which govern response of a system. Since it is based on energy flow, path analysis is straight forward. In this article it is described how to extract the dominant path in a complex model using SEA and VA One . As a result the subsystems in the dominant path are displayed in the 3d window (All other subsystems are hidden).

Ricardo

Alvarez

Vibro-Acoustics

How to report and talk about simulation time in an objective manner

Reporting or talking about simulation time is a difficult subject. In the article a way to manage this problem in an objective manner is given.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

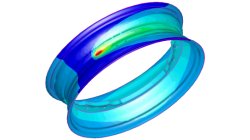

The transient method – the third out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The third one – the transient method – is used when not only distortion but also residual stresses and microstructure need to be evaluated. The part size allows running a heat source gradually. Compare it with a formability evaluation in sheet metal forming. A motorcycle rim may serve as an example.

Harald

Porzner

Welding & Assembly

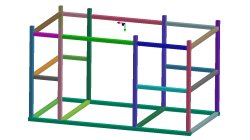

The instantaneous method – the second out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The second one – the instantaneous method – is used when not only distortion but also residual stresses and micro-structure needs to be evaluated, but welded designs are so huge that it would make no more sense to use a classic transient method with a moving heat source – the simulation time would be too long. Compare it with a feasibility evaluation in sheet metal forming. A frame as produced in machine building, with more than 100 welds, may serve as an example.

Harald

Porzner

Welding & Assembly

The shrinkage method – the first out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The first one – the shrinkage method – is used in the feasibility and planning phase. Goal is to get as fast as possible an estimation. Compare it with a one-step method in sheet metal forming.

Harald

Porzner

Welding & Assembly