- Home

- Resources

- Tips & Tricks

Tips & Tricks

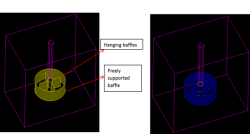

Adding Baffles to an Unstructured domain in CFD-GEOM

While meshing the geometries of industrial significance like mixing tanks, reactor and heat exchangers, we may encounter baffles which have negligible thickness but significant area to impact the physics of the problem in terms of momentum and heat transfer. These surfaces may be free-standing or connected to other surfaces from the domain.

Abraham

Meganathan

CFD

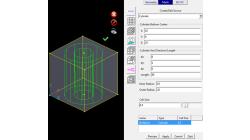

New Mesh Sources in CFD-GEOM for Triangle and Tetrahedral meshing

Corner Point Sources, Surface Interior Sources and Tet Sources have been available in CFD-GEOM for several years, allowing for refinements during certain phases of mesh generation.

Abraham

Meganathan

CFD

IDO.Cooperate via a Gateway PC (USER)

In this Tips & Tricks document you will find a step to step description how to set up a Client as a Gateway PC for a IDO.Cooperate Session.

Frank

Schoeffel

Virtual Reality

Best Practices for Video Rendering (USER)

In this Tips & Tricks document you will find the recommended settings and hints for rendering videos from IC.IDO.

Abderrazak

Mejdi

Virtual Reality

IDO.Present - Media Recording (VIDEO)

This tutorial will show you how to record your VDP / IC.IDO visualization screen. After you have studied this tutorial, you will be able to record your visualization screen and change the format or quality of the rendered video.

Abderrazak

Mejdi

Virtual Reality

Clipping Plane Parameters (USER)

The clipping plane functionality allows the user to increase the performance of his session. Some geometries can cause problems with the default clipping parameters. This article will explain some hints to avoid such problems.

Abderrazak

Mejdi

Virtual Reality

How to update the ProcessControl? (ADMINISTRATOR)

This document explains how to update the ProcessControl Software of your Virtual Reality Cluster.

Abderrazak

Mejdi

Virtual Reality

How to report and talk about simulation time in an objective manner

Reporting or talking about simulation time is a difficult subject. In the article a way to manage this problem in an objective manner is given.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

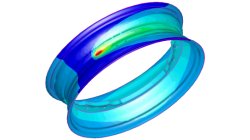

The transient method – the third out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The third one – the transient method – is used when not only distortion but also residual stresses and microstructure need to be evaluated. The part size allows running a heat source gradually. Compare it with a formability evaluation in sheet metal forming. A motorcycle rim may serve as an example.

Harald

Porzner

Welding & Assembly