- Home

- Resources

- Tips & Tricks

Tips & Tricks

How to report and talk about simulation time in an objective manner

Reporting or talking about simulation time is a difficult subject. In the article a way to manage this problem in an objective manner is given.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

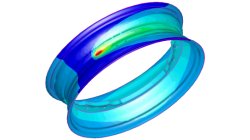

The transient method – the third out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The third one – the transient method – is used when not only distortion but also residual stresses and microstructure need to be evaluated. The part size allows running a heat source gradually. Compare it with a formability evaluation in sheet metal forming. A motorcycle rim may serve as an example.

Harald

Porzner

Welding & Assembly

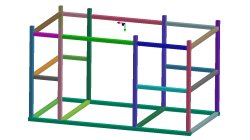

The instantaneous method – the second out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The second one – the instantaneous method – is used when not only distortion but also residual stresses and micro-structure needs to be evaluated, but welded designs are so huge that it would make no more sense to use a classic transient method with a moving heat source – the simulation time would be too long. Compare it with a feasibility evaluation in sheet metal forming. A frame as produced in machine building, with more than 100 welds, may serve as an example.

Harald

Porzner

Welding & Assembly

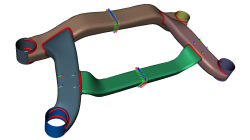

The shrinkage method – the first out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The first one – the shrinkage method – is used in the feasibility and planning phase. Goal is to get as fast as possible an estimation. Compare it with a one-step method in sheet metal forming.

Harald

Porzner

Welding & Assembly

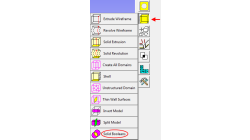

Working with Solids in CFD-GEOM - Part 1: Boolean Operations

Given that today’s users may import several complex parts into CFD-GEOM, this tip will demonstrate how to use the Solid Boolean Union Option to combine several parts into one.

Abraham

Meganathan

CFD

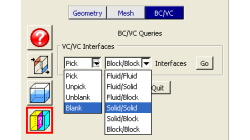

Using the BC/VC Queries tool in CFD-GEOM

Have you ever whished that you could blank/unblank or pick/unpick only interfaces in a CFD-GEOM model? You can now with the BC/VC Queries tool. This tool allows you to pick, unpick, blank or unblank all the interfaces of the current model based on the interface type (Fluid/Fluid, Fluid/Solid, etc.).

Abraham

Meganathan

CFD

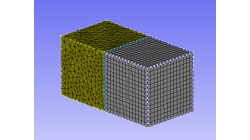

How to create Pyramid cells on structured-unstructured domain interfaces in CFD-GEOM

CFD-GEOM can be used to construct a variety of cell shapes: quadrilaterals (2D) and hexahedrals (3D) for structured meshes; triangles (2D) as well as tetrahedrals and polyhedral/honeycomb (3D) for unstructured meshes; prisms and pyramids (3D) for semi-structured meshes.

Abraham

Meganathan

CFD

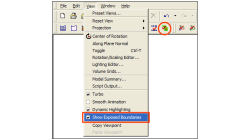

New Exposed Boundaries Visualization tool in CFD-GEOM

One of the various new features introduced in CFD-GEOM V2009.2 is the ‘Exposed Boundaries’ visualization tool. This tool allows users to quickly visualize those areas where closure problems remain in an otherwise closed and “watertight” model.

Abraham

Meganathan

CFD

Repairing Imported CAD Geometries in CFD-GEOM

In most cases, importing CAD files in CFD-GEOM results in a clean geometry that can be directly used for further processing and/or meshing. However, for complex models, it is possible that the imported geometry has missing, untrimmed or defective surfaces that need to be manually repaired.

Abraham

Meganathan

CFD