- Home

- Resources

- Tips & Tricks

Tips & Tricks

How to simulate welding process with variable weld speed and Heat power ?

In real process, the user changes the velocity depending to the distance already covered or still to cover in welding process. To better reproduce the start and the end of a welding process, the velocity must be able to vary during at least these two phases as well as the heat source power. And to be more generic, this feature introduces a time dependency of the heat source velocity and its power density.

Mandikizinoyou

Taro

Welding & Assembly, Virtual Performance, Virtual Integration Platform

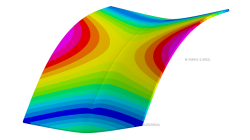

Horse saddle distortion modelling in Visual Weld

Welding of structures involves complex interactions between thermal, metallurgical and mechanical phenomena leading to residual stresses and distortions, which play a major role during subsequent service of these structures. Controlling material characteristics, residual stress and keep distortion within tolerances via the computer can significantly enhance the performance, the quality of the product and the structure’s service life

Mandikizinoyou

Taro

Sheet Metal Forming, Virtual Manufacturing, Multiphysics, Welding & Assembly

Overview of CSM Welding Advisor in Visual Environment 18.0.2

This tip is to give an overview of new CSM welding advisor in Visual Environment 18.0.2. This new advisor comes in replacement of Visual Welding advisor and uses Assembly solver to perform transient welding simulation.

Mandikizinoyou

Taro

Sheet Metal Forming, Virtual Manufacturing, Welding & Assembly

Demonstrator of typical Stamp-Assembly process in automotive BiW manufacturing

New Stamp-Assembly non-confidential tutorial available

Jan

Bejvl

Sheet Metal Forming, Welding & Assembly, Virtual Integration Platform

e-Café #2 PYFUN, PYSTOP - Programmer ses propres critères d'arrêt de calcul

Comment programmer des critères d'arrêt de calcul en Python

Jean-Charles

Paulin

Virtual Performance

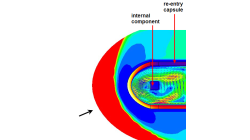

CFD-FASTRAN/CFD-ACE+ coupling for thermal environment simulations

In certain applications, different regions of the computational domain experiences flow conditions that are so different that it is very difficult for a single solver to produce accurate results at the extremes. In many situations, such problems can be separated and solved using loosely coupled solvers. Each solver is chosen to provide highly accurate solutions for the prevailing flow conditions.

Abraham

Meganathan

CFD

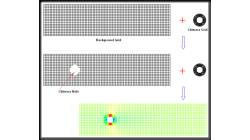

Avoiding Chimera Errors in CFD-FASTRAN

This note discusses a common error encountered by users when trying chimera meshes in CFD-FASTRAN. Such errors are easy to avoid and hopefully this note will assist you.

Abraham

Meganathan

CFD

Motion Model Dependencies in CFD-FASTRAN

Moving-body models available in CFD-FASTRAN are highly suited to simulate complex prescribed and six-degree-of-freedom (6DOF) motions of rigid bodies. In many engineering problems, this translates to multiple bodies moving relative to one another.

Abraham

Meganathan

CFD

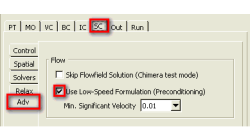

Low Mach Preconditioning and Dual Time Stepping in CFD-FASTRAN

Density-based schemes employing time-marching procedures available in CFD-FASTRAN provide excellent stability and convergence characteristics for high-speed compressible flows (typically M >0.5).

Abraham

Meganathan

CFD

Axisymmetric 2D Convergent-Divergent Boattail Nozzle Simulation Using CFD-FASTRAN

The NASA D-1.22-L boattail nozzle configuration was obtained from the MADIC (Multidisciplinary and Design Industrial Consortium) program. The geometry definition and the flow conditions are documented in NASA TP 1766 [1]. This user tip presents a validation of numerical methods against experimental data.

Abraham

Meganathan

CFD