- Home

- Resources

- Tips & Tricks

Tips & Tricks

Overview of PAM-DIEMAKER for CATIA V5

Quick overview of PAM-DIEMAKER for CATIA V5 workflow and additional functionalities for following operations, from design up to simulation in PAM-STAMP

Mark

Vrolijk

Sheet Metal Forming

Construction tools : Generic Editors - PAM-DIEMAKER for CATIA V5

DM Construction Editor allows quick creation of high quality surfaces using existing underlying surfaces in combination with DIEMAKER Generic Operations. DM Hole Editor is an adaptation of Construction Editor used specifically for holes filling.

Jana

Maradova

Sheet Metal Forming

Construction tools : Generic Operations - PAM-DIEMAKER for CATIA V5

Video presenting main functionalities of generic surface operations within PAM-DIEMAKER for CATIA V5

Jana

Maradova

Sheet Metal Forming

Advanced Piercing - PAM-DIEMAKER for CATIA V5 2020.0

Presentation of the new functionality of Advanced Piercing within PAM-DIEMAKER for Catia V5 2020.0

Matthias

Hoss

Sheet Metal Forming

Trimming segments improvements - PAM-DIEMAKER for CATIA V5 2020.0

Trimming segment functionality has been improved within PAM-DIEMAKER for CATIA V5 2020.0 Movie is presenting how it works.

Matthias

Hoss

Sheet Metal Forming

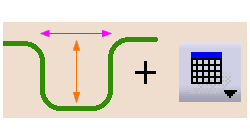

Geometrical drawbeads with Design Table

CATIA V5 offers powerful functionality to modify existing geometry “from outside” via DESIGN TABLE. PAM DIEMAKER for CATIA V5 also supports this procedure with some prerequisites.

Matthias

Hoss

Sheet Metal Forming

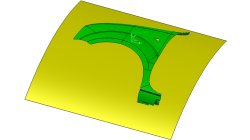

How to use Blank Holder functionality in PAM-DIEMAKER for CATIA V5

This video shows how to use Blank Holder functionnality to create mono surface Blank Holder shapes and combination of several Blank Holder patches.

Matthias

Hoss

Sheet Metal Forming

How to Obtain Best Results within Reasonable Time from a Heat Treatment Simulation

Heat treated parts are in most cases not clamped during heat treatment, for an FEM analysis, at least a static determined clamping is needed that does not allow any rigid body motion.

Yonggang

Duan

Welding & Assembly

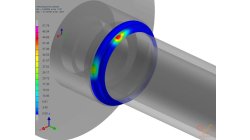

Stamping/HT Chaining of 3D Ring - Restart tool in Visual Heat Treatment

This article is to show effects of heat treatment on stresses when industrial mechanical parts are stamped (or welded) by 3 typical heat treatment steps: Heating, Quenching and Tempering. Tempering is generally considered effective in relieving stresses induced by quenching in addition to lowering hardness to within a specified range, or meeting certain mechanical property requirements.

Yonggang

Duan

Welding & Assembly

Heat Power display in Visual Weld

The aim of this development in Visual Weld 14.5 + Sysweld 2019.0 is to display the Power Density. Currently, this functionality is only available in the old SysWeld GUI. The new functionality "Heat Power Display" is available through the "Welding Utilities" menu of Visual Weld.

Yonggang

Duan

Welding & Assembly