- Home

- Resources

- Tips & Tricks

Tips & Tricks

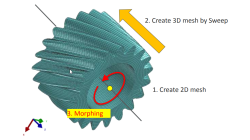

Solid elements morphing by twist in Visual Mesh

In the case of 3D meshes, the term morph can be interpreted as the change of appearance of a graphical object. The morphing process is then defined as the construction of an animated sequence corresponding to the gradual transition between two different objects, so-called source (initial) and target (final) models. The objective of a morphing method is to compute a transformation ensuring a visually pleasant transition between the two, source and target shapes

Mandikizinoyou

Taro

Multiphysics, Welding & Assembly

Demonstrator of typical Stamp-Assembly process in automotive BiW manufacturing

New Stamp-Assembly non-confidential tutorial available

Jan

Bejvl

Sheet Metal Forming, Welding & Assembly, Virtual Integration Platform

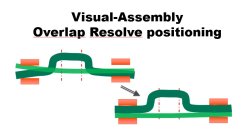

Visual-Assembly Overlap Resolve positioning

The most effective way how to position your distorted components into the clamping system.

Jan

Bejvl

Welding & Assembly, Virtual Integration Platform

Visual-Mesh for Assembly setup - How to create mesh for shell analysis from CAD.

Short video how to create shell mesh from CAD using Visual-Mesh application.

Ksenia

Troyanova

Welding & Assembly, Virtual Integration Platform

Delta T Offset For Bowing Effect in Assembly Process

In case of butt joint of two plates, in reality, there is an eccentricity e between the neutral phase of bending and the centre of the tendon force caused by the weld which causes the typical horse saddle of a butt welded flat plate.. A functionality Delta T Offset has been developed in order to overcome the limitation due to the shrinkage methodology that cannot provide correct results for a butt joint with a non-symmetrical welding. With this new development, it will be possible to apply an offset value on the thermal loading between upper and lower surfaces of shell. In consequence, the horse saddle effect of a butt welded flat plate is produced with Assembly solution.

Yonggang

Duan

Welding & Assembly

CFD-VIEW Colormap Options: Static, Dynamic, and Cumulative

The Colormap Settings panel in CFD-VIEW assigns colors to data sets. Identical data values on an object are displayed with the same color if they are using the same colormap display. Three options offer the user the opportunity to select the mode for updating the colormap as the underlying data changes, for example during transient simulations. These options are: Static, Dynamic, and Cumulative

Santosh

Kini

CFD

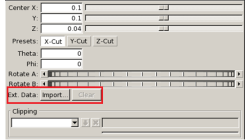

Importing an arbitrary STL surface for post-processing in CFD VIEW

When using the Arbitrary-Cut operator, you have the option to directly import an external surface in STL format into the model. This option, which was first made available in V2013.4, underwent significant performance improvements in V2014.0. This option provides the ability to plot data and process information on any arbitrarily shaped surface. The import process involves reading the STL file and computing the intersections between this surface and the model’s volume cells. Results on the imported surface are interpolated from the intersected volume cells and are independent of the surface mesh size of the STL as long as the surface is properly represented.

Abraham

Meganathan

CFD

Grouping option for CFD-VIEW Data Import

Grouping feature in CFD-ACE+ GUI and CFD-VIEW comes in handy when working with complex industrial models. This feature allows putting BC patches or VC entities into a group that can be manipulated easily, to either set up properties or display specific post-processing attributes.

Abraham

Meganathan

CFD

CFD-VIEW Scripting is easier than ever with Journaling

In addition to the numerous options and tools available via the CFD-VIEW user interface, the scripting capability of CFD-VIEW allows you to perform complex data processing on your simulation results, and gives you the option to run the post-processing phase of your simulation in batch mode.

Abraham

Meganathan

CFD

CFD-VIEW: Working with cell-center data in batch mode

Many improvements have been made in CFD-VIEW that allows the manipulation of cell-center data. The latest cell-center data additions implemented in CFD-VIEW V2011.0 include, for example, support for the MinMax Probe and the Calculator.

Abraham

Meganathan

CFD