- Home

- Resources

- Tips & Tricks

Tips & Tricks

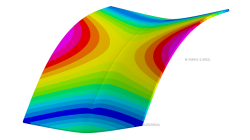

Horse saddle distortion modelling in Visual Weld

Welding of structures involves complex interactions between thermal, metallurgical and mechanical phenomena leading to residual stresses and distortions, which play a major role during subsequent service of these structures. Controlling material characteristics, residual stress and keep distortion within tolerances via the computer can significantly enhance the performance, the quality of the product and the structure’s service life

Mandikizinoyou

Taro

Sheet Metal Forming, Virtual Manufacturing, Multiphysics, Welding & Assembly

Restart Sysweld thermo-metallurgy and mechanical calculation in batch mode

The aim of this article consists to show sysweld/systus users how to perform a restart computation when a calculation run in batch mode is stopped in middle for some reasons or not.

Mandikizinoyou

Taro

Virtual Manufacturing, Multiphysics, Welding & Assembly

Overview of CSM Welding Advisor in Visual Environment 18.0.2

This tip is to give an overview of new CSM welding advisor in Visual Environment 18.0.2. This new advisor comes in replacement of Visual Welding advisor and uses Assembly solver to perform transient welding simulation.

Mandikizinoyou

Taro

Sheet Metal Forming, Virtual Manufacturing, Welding & Assembly

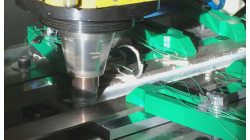

Friction Stir Welding modelling with an Axi-symmetric tool

Friction Stir Welding (FSW) is an innovative technology, which allows a solid junction of heterogeneous alloys, using a wear-resistant rotary tool that follows the welding seam. ESI Welding solution allows todays to predict temperature generated by FSW process. The proposed methodology is based on local approach that cannot give global distortion of the welded components. The aim of this article is to show how user can setup it own FSW process and run the computation using Visual Weld application

Mandikizinoyou

Taro

Virtual Manufacturing, Welding & Assembly

e-café #12 : L’outil de post traitement ESI PLAYER™

Découvrez comment exporter et exploiter les résultats de ProCAST™ ou QuikCAST™ dans l’interface ESI-PLAYER™

Mathieu

Moerckel

Casting

e-Café #7 - Maillage volumique avec Visual-CAST™ 16.0

Créez le maillage volumique à l’aide de la fonction Grid Definition dans Visual-CAST™ 16.0

Mathieu

Moerckel

Casting

e-café #5- Pilotage du refroidissement par thermocouple à l’aide de ProCAST™ et QuikCAST™

Pilotage du refroidissement par thermocouple à l’aide de ProCAST™ et QuikCAST™

Mathieu

Moerckel

Casting

e-café #4- Modélisation de l’emballage (Wrap) à l’aide de ProCAST™

Modélisation de l’emballage (Wrap) à l’aide de ProCAST™

Mathieu

Moerckel

Casting

e-café #3- Modélisation des opérations de poteyage et soufflage à l’aide Quik CAST™

Modélisation des opérations de poteyage et soufflage à l’aide Quik CAST™

Mathieu

Moerckel

Casting

Parallel processing

“To pull a bigger wagon, it is easier to add more horses than to grow a gigantic horse.” This paraphrased quotation nicely expresses the basic concept of parallel processing. The speed of sequential computers has been doubling every eighteen months, according to Moore’s law. However, at any given time, that speed is limited by the state of the art in integrated circuit design and manufacturing. To circumvent that limitation, it is possible to split a given computationally intensive task among multiple processors working simultaneously.

Bohus

Ulrych

Casting