- Home

- Resources

- Tips & Tricks

Tips & Tricks

Make an independent setup from existing pre and rst files in PAM-STAMP

Sometimes only rst files there are available and dependent pre file of an intermediate stage setup (lost data, picking with a process variant, …), which is not possible to run in another PAM-STAMP version, usually in newer version. It is possible to create a pre file independent on preceding rst files.

Tomas

Nosek

Sheet Metal Forming

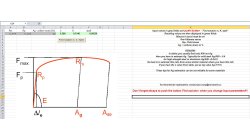

Determination of Krupkowsky parameters for hardening curve

In case there are no measured material data for simulation purposes, it is possible to determine hardening curve from information usually provided by material supplier.

Tomas

Nosek

Sheet Metal Forming

Influences of Solidification Length and Pressure Intensification on Gas Shrinkage Microporosity in Casting Components

Porosity in castings is a major defect since it affects the mechanical properties. In particular porosities are sites for the initiation of fatigue cracks. Therefore, the reduction of porosity fraction and size, the control of porosity distribution and morphology are crucial for the optimization of mechanical resistance of as cast components.

Casting

Grouping parts during data import in CFD-VisCART

When dealing with complex industrial models such as cars and airplanes, hundreds of parts need to be managed. Each one of these parts may also be subdivided into different components. In order to easily manipulate these different parts and components in CFD-VisCART, you can make use of the grouping feature.

Abraham

Meganathan

CFD

How to import a PAM-STAMP result into CATIA V5 with VRML export format ?

For a comparison of the virtual stamped part and the nominal CATIA V5 part one can use PAM-STAMP, or go back to CATIA. Since the meshed part is not easily converted into surfaces again, one solution is to use an overlay of the CAD part and of a VRML export of the stamp part.

Matthias

Schroeder

Sheet Metal Forming

How to encrypt material data sets in PAM-STAMP?

Major automotive companies spend a lot of money to describe all materials used in their simulation processes. To ensure simulation quality also at supplier sites, they want to give the material data sets to them, but not for free. One half of the solution is material encryption, the other a predefined expiration date.

Matthias

Schroeder

Sheet Metal Forming

Boundary layer meshing with CFD-ACE+ [video format]

The accuracy of a CFD solution is strongly dependent on how well the mesh resolves geometry and flow features. This is especially true for near wall regions (boundary layer) where viscous forces are not negligible compared to inertial forces.

Abraham

Meganathan

CFD

CFD-VisCART: Mesh Extrusion

In most CFD simulations, it is required to place inlets/outlets far enough from the region of interest in order to reduce their influence on the solution. In many applications, this can be done by extruding existing inlets/outlets BC patches away from the domain.

Abraham

Meganathan

CFD

Small collection of 3D meshed symbols for illustration purposes

During a project the need to visualize the functionality in 3D arose and some 3D symbols were created, which are now made available as a goody.

Matthias

Schroeder

Sheet Metal Forming

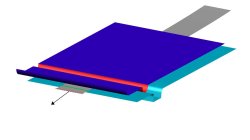

How to find out what forces are working inside the sheet or tube section ?

If you need insight on the restraining force of a geometrical drawbead or want to know the transmitted force in a sheet or tube section, you can define a force gauge.

Matthias

Schroeder

Sheet Metal Forming