- Home

- Resources

- Tips & Tricks

Tips & Tricks

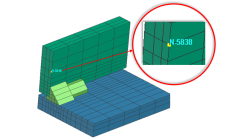

Display mesh nodes in Visual Viewer based on internal number ID

Today it is not possible to display internal number of node within visual viewer. The only way is to display internal number within Sysweld/systus solver, check for the corresponding user defined one and come back in visual viewer to display the user define one. Meanwhile in the .Log file only internal nodes are listed. ITERATION 0 MAX. RESIDUE 0.414E-01 NODE (INT) 14817 COMPONENT 1

Mandikizinoyou

Taro

Multiphysics, Welding & Assembly

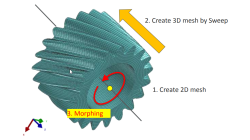

Solid elements morphing by twist in Visual Mesh

In the case of 3D meshes, the term morph can be interpreted as the change of appearance of a graphical object. The morphing process is then defined as the construction of an animated sequence corresponding to the gradual transition between two different objects, so-called source (initial) and target (final) models. The objective of a morphing method is to compute a transformation ensuring a visually pleasant transition between the two, source and target shapes

Mandikizinoyou

Taro

Multiphysics, Welding & Assembly

How to simulate welding process with variable weld speed and Heat power ?

In real process, the user changes the velocity depending to the distance already covered or still to cover in welding process. To better reproduce the start and the end of a welding process, the velocity must be able to vary during at least these two phases as well as the heat source power. And to be more generic, this feature introduces a time dependency of the heat source velocity and its power density.

Mandikizinoyou

Taro

Welding & Assembly, Virtual Performance, Virtual Integration Platform

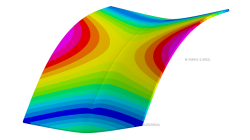

Horse saddle distortion modelling in Visual Weld

Welding of structures involves complex interactions between thermal, metallurgical and mechanical phenomena leading to residual stresses and distortions, which play a major role during subsequent service of these structures. Controlling material characteristics, residual stress and keep distortion within tolerances via the computer can significantly enhance the performance, the quality of the product and the structure’s service life

Mandikizinoyou

Taro

Sheet Metal Forming, Virtual Manufacturing, Multiphysics, Welding & Assembly

Restart Sysweld thermo-metallurgy and mechanical calculation in batch mode

The aim of this article consists to show sysweld/systus users how to perform a restart computation when a calculation run in batch mode is stopped in middle for some reasons or not.

Mandikizinoyou

Taro

Virtual Manufacturing, Multiphysics, Welding & Assembly

Demonstrator of typical Stamp-Assembly process in automotive BiW manufacturing

New Stamp-Assembly non-confidential tutorial available

Jan

Bejvl

Sheet Metal Forming, Welding & Assembly, Virtual Integration Platform

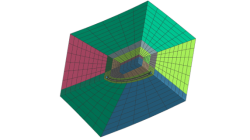

Crack Mesh Application

To insert Crack in a 3D model, an application named Crack Insertion is available

Sandrine

Dischert

Multiphysics, Virtual Integration Platform

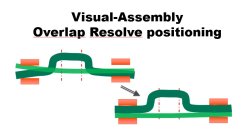

Visual-Assembly Overlap Resolve positioning

The most effective way how to position your distorted components into the clamping system.

Jan

Bejvl

Welding & Assembly, Virtual Integration Platform

Visual-Mesh for Assembly setup - How to create mesh for shell analysis from CAD.

Short video how to create shell mesh from CAD using Visual-Mesh application.

Ksenia

Troyanova

Welding & Assembly, Virtual Integration Platform

Visual-Environment Highlight of Visual-CFD: Multiphase Flow

In fluid mechanics, multiphase flow is the simultaneous flow of materials with two or more thermodynamic phases. These phases may consist of one chemical component (e.g. flow of water and water vapour), or several different chemical components (e.g. flow of oil and water). Based in user’s intertest and type of problems, multiphase problems can be solved as VOF or euler-euler flow. In Visual-CFD, both approaches are supported for two or more than two phases, with or without heat. The solvers used for multiphase simulations involve the famous MULES method for capturing interfaces between the fluids.

Raj Kumar

Barnawal

Virtual Integration Platform