Visual-Weld - Heat Treatment

Be able to translate the heat treatment process into a virtual model that can simulate this process and its heat effects; simulate heating, carburization if required, quenching and tempering; assess computed temperature, phase transformations, distortion, and residual stresses; go from geometry to mesh to a simulation model to assessing computed results and generate models that run stable, as fast as possible, still delivering accurate results

Audience

Engineers concerned with heat treatment of metal part

Prerequisites

Basic Knowledge of CAD, CAE, and heat treatment engineering.

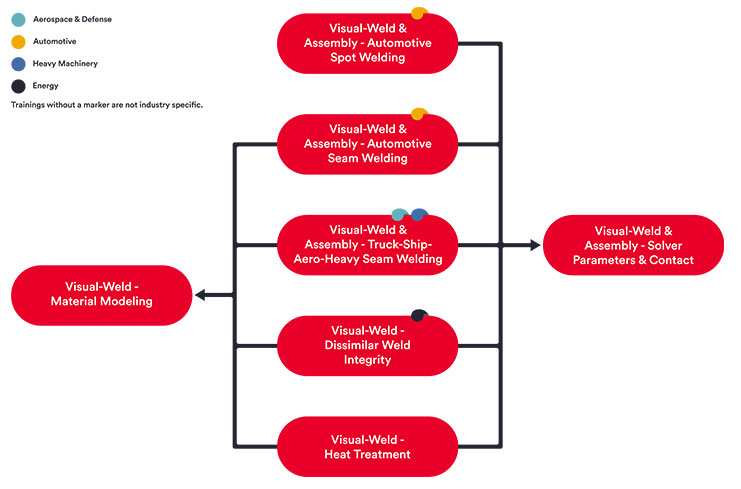

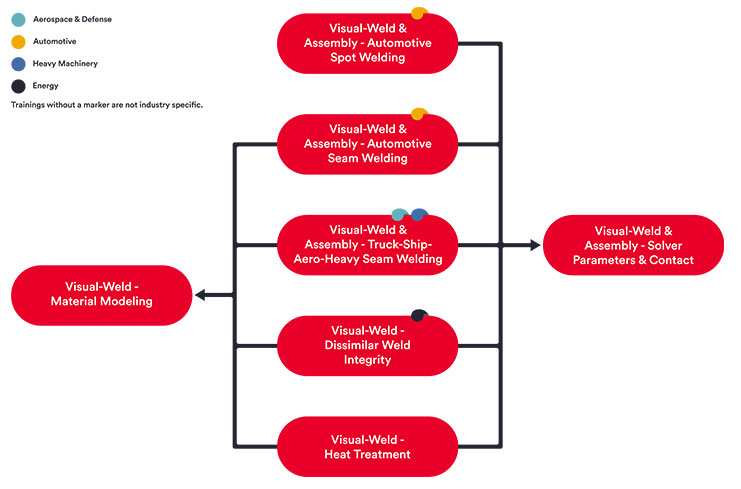

LEARNING PATH

SUGGESTED COURSES

DESCRIPTION

Operate the graphic user interface of Visual Environment, focus heat treatment. Generate 2D solid and 3D solid heat treatment models. Best practices for Graphic user interface; Geometry to mesh; Material; Process definition; Quenching media; Solution parameters; Model check; Simulation runs, simulation monitoring, file structure; Troubleshooting and Post-processing

No suitable date or place?

Set up a private training

TRAINING PROGRAM

Day 1

- How to operate the Graphic User Interface & create own tailored toolbars

- How to go from a CAD model to a 2D solid mesh

- How to go from a CAD model to a 3D solid mesh

- How to make sure meshes are good to go

Day 2

- Jominy end quench test

- Set up and run the jominy end quench test

- Understand the contents of a material database, manage material databases

- Understand how to modify public databases to own needs (basics)

- Manage quenching media and process windows

- Understand the influence of process parameters, and material on computed results

- Assess computed temperature, phase transformations, distortion, and residual stresses

- Assess hardness and compare with measurements

- Modify the CCT diagram to match computed with measured hardness

- Use own material and quenching media

- Investigate into layered meshing density and computed results corresponding to own cases

- Mesh density, time stepping and precision – Best performance without compromising accuracy

- Jominy specimen – heating & diving

- Use the jominy specimen to simulate heating and diving into a quenching media

- Jominy specimen – carburization and quenching

- Use the jominy specimen to simulate heating, carburization, and quenching

- Full model process simulation

- Application to a representative large and complex model

Day 3

- Continuation large model process validation

- Industrial example