- Home

- Resources

- Tips & Tricks

Tips & Tricks

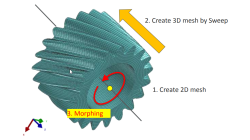

Solid elements morphing by twist in Visual Mesh

In the case of 3D meshes, the term morph can be interpreted as the change of appearance of a graphical object. The morphing process is then defined as the construction of an animated sequence corresponding to the gradual transition between two different objects, so-called source (initial) and target (final) models. The objective of a morphing method is to compute a transformation ensuring a visually pleasant transition between the two, source and target shapes

Mandikizinoyou

Taro

Multiphysics, Welding & Assembly

How to simulate welding process with variable weld speed and Heat power ?

In real process, the user changes the velocity depending to the distance already covered or still to cover in welding process. To better reproduce the start and the end of a welding process, the velocity must be able to vary during at least these two phases as well as the heat source power. And to be more generic, this feature introduces a time dependency of the heat source velocity and its power density.

Mandikizinoyou

Taro

Welding & Assembly, Virtual Performance, Virtual Integration Platform

Demonstrator of typical Stamp-Assembly process in automotive BiW manufacturing

New Stamp-Assembly non-confidential tutorial available

Jan

Bejvl

Sheet Metal Forming, Welding & Assembly, Virtual Integration Platform

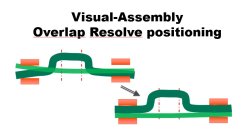

Visual-Assembly Overlap Resolve positioning

The most effective way how to position your distorted components into the clamping system.

Jan

Bejvl

Welding & Assembly, Virtual Integration Platform

Visual-Mesh for Assembly setup - How to create mesh for shell analysis from CAD.

Short video how to create shell mesh from CAD using Visual-Mesh application.

Ksenia

Troyanova

Welding & Assembly, Virtual Integration Platform

e-Café #2 PYFUN, PYSTOP - Programmer ses propres critères d'arrêt de calcul

Comment programmer des critères d'arrêt de calcul en Python

Jean-Charles

Paulin

Virtual Performance

Delta T Offset For Bowing Effect in Assembly Process

In case of butt joint of two plates, in reality, there is an eccentricity e between the neutral phase of bending and the centre of the tendon force caused by the weld which causes the typical horse saddle of a butt welded flat plate.. A functionality Delta T Offset has been developed in order to overcome the limitation due to the shrinkage methodology that cannot provide correct results for a butt joint with a non-symmetrical welding. With this new development, it will be possible to apply an offset value on the thermal loading between upper and lower surfaces of shell. In consequence, the horse saddle effect of a butt welded flat plate is produced with Assembly solution.

Yonggang

Duan

Welding & Assembly

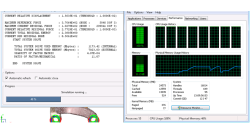

How to report and talk about simulation time in an objective manner

Reporting or talking about simulation time is a difficult subject. In the article a way to manage this problem in an objective manner is given.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

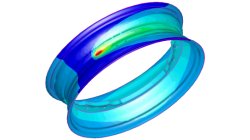

The transient method – the third out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The third one – the transient method – is used when not only distortion but also residual stresses and microstructure need to be evaluated. The part size allows running a heat source gradually. Compare it with a formability evaluation in sheet metal forming. A motorcycle rim may serve as an example.

Harald

Porzner

Welding & Assembly