- Home

- Resources

- Tips & Tricks

Tips & Tricks

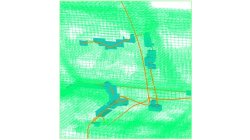

How to simulate welding process with variable weld speed and Heat power ?

In real process, the user changes the velocity depending to the distance already covered or still to cover in welding process. To better reproduce the start and the end of a welding process, the velocity must be able to vary during at least these two phases as well as the heat source power. And to be more generic, this feature introduces a time dependency of the heat source velocity and its power density.

Mandikizinoyou

Taro

Welding & Assembly, Virtual Performance, Virtual Integration Platform

e-Café #2 PYFUN, PYSTOP - Programmer ses propres critères d'arrêt de calcul

Comment programmer des critères d'arrêt de calcul en Python

Jean-Charles

Paulin

Virtual Performance

How to model Cable Networks & Connectors?

This paper is aimed at describing the modeling process to be applied to the terminal connectors of a Cable Network when focusing on 3D/Multiconductor Transmission Lines (MTL) coupling

Jean-Claude

Kedzia

Electromagnetics

How to manage small sized Reference Boxes?

This paper is introducing the “–RB” option of the FD mesh generator allowing PAM-CEM/FD users to manage one limited part of a complete CAD model, without any hand-made cleaning stage

Jean-Claude

Kedzia

Electromagnetics

How to avoid oscillatory phenomena with short circuited terminals of Cable Networks ?

Cable Networks with short-circuited terminals may exhibit Common-Mode (CM) currents with a highly oscillatory behavior. This article illustrates one solution to eliminate such behavior by considering lossy dielectric coatings varying with the frequency.

Jean-Claude

Kedzia

Electromagnetics

FD Interpolating Scheme near Metallic Structures

This article illustrates the PAM-CEM/FD interpolation scheme applied to compute the tangential electric field along wires’ path running near metallic structures (and aimed at avoiding the management of field components on both sides of the surface).

Jean-Claude

Kedzia

Electromagnetics

3D/Multiconductor Transmission Lines (MTL) Coupling VS. Stand-Alone FDTD (Accuracy)

This article is aimed at comparing the 3D/Multiconductor Transmission Lines (MTL) coupling accuracy with the PAM-CEM/FD stand-alone use, when applied to simplified wired models. Recommendations for good agreement are also proposed.

Jean-Claude

Kedzia

Electromagnetics

How to report and talk about simulation time in an objective manner

Reporting or talking about simulation time is a difficult subject. In the article a way to manage this problem in an objective manner is given.

Harald

Porzner

Welding & Assembly

Materials in the database - Which material properties to use with respect to the three methods to simulate the heat effects of welding

A material is described with exactly one set of material properties. In simulation engineering - depending on the applied method and the moment in time when the simulation is carried out in the product development cycle - only subsets of a full material data set might be required. In this article is outlined which subset is used for which purpose, what is available in the database, and what can be simulated.

Harald

Porzner

Welding & Assembly

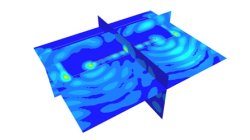

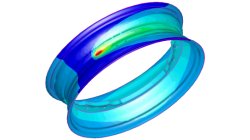

The transient method – the third out of three methods to simulate the heat effects of welding

In order to meet different requirements from first design to start of production, three different methods are available in the Virtual Welding & Assembly Suite from ESI. The third one – the transient method – is used when not only distortion but also residual stresses and microstructure need to be evaluated. The part size allows running a heat source gradually. Compare it with a formability evaluation in sheet metal forming. A motorcycle rim may serve as an example.

Harald

Porzner

Welding & Assembly