PAM-DISTORTION – Basic Training

Be able to model, analyze results and optimize through simulation - Standard injection or infusion processes considering thermal effects including preheating and curing processes. Be able to identify required data and to determine proper assumptions for simulations

Audience

CAE engineers, Process engineers, Material engineers, Designers

Prerequisites

Basic FEA knowledge and basic composites material knowledge

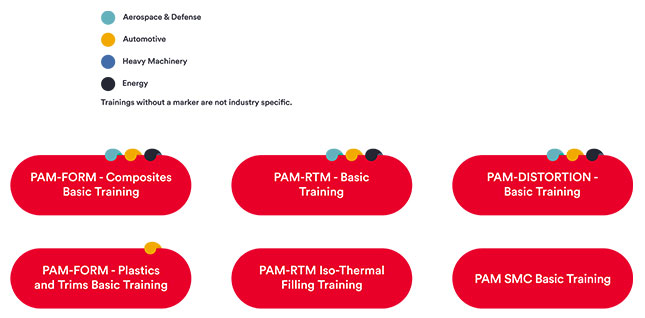

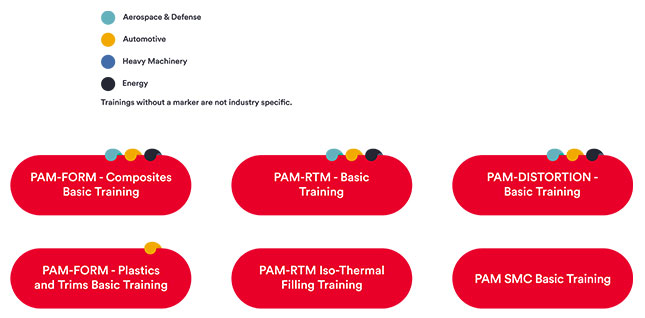

LEARNING PATH

SUGGESTED COURSES

DESCRIPTION

This training is meant for engineers responsible for designing manufacturing processes such as RTM/infusion for composite parts. This training relies on PowerPoint presentation and practical use cases executed on workstation. This training will allow the trainee to confidently create simulation models.

No suitable date or place?

Set up a private training

TRAINING PROGRAM

Day 1 – Physics and GUI Description

- Introduction on physics, modeling, material requirements for the curing simulation

- Workflow and GUI description.

- Curing simulation on basic part geometry

- From CAD (1) to simulation: Modeling, laminate creation, element orientation and boundary conditions

(1) This training course includes initiation to Visual-Mesh regarding the specific meshing needs of the treated models. However, it does not include a complete Visual-Mesh training that can be ordered separately.

Day 2 – Isothermal Analysis

- Virtual testing for Lamina and laminate material characterization

- Distortion simulation on L-Shape geometry

- Single stage simulation: Free distortion during curing

- Multi-stage simulation: Distortion during and after curing (without mold)

- Curing simulation on L-Shape geometry with mold: Thermal interaction with mold

- Distortion simulation on L-Shape geometry with mold: Mechanical interaction with mold

Day 3 – Draping effect, Non-Isothermal and Fluid-Mechanic analysis

- Gravity effect

- Post-cured cycles

- Trimming stage

- Co-cured or assembled with adhesive