PAM-FORM - Plastics and Trims Basic Training

Be able to model, analyze results and optimize through simulation: Standard injection or infusion processes considering thermal effects including preheating and curing processes Be able to identify required data and to determine proper assumptions for simulations.

Audience

CAE engineers, Process engineers, Material engineers, Designers

Prerequisites

Basic FEA knowledge and basic composites material knowledge

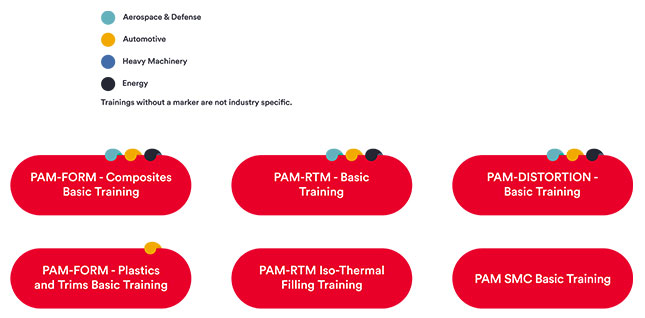

LEARNING PATH

SUGGESTED COURSES

DESCRIPTION

This training is meant for engineers responsible for designing thermoforming processes of auto interior parts (instrument panels, acoustic liners…) or packages. This training relies on PowerPoint presentation and practical use cases executed on workstation. This training will allow the trainee to confidently create simulation models.

No suitable date or place?

Set up a private training

TRAINING PROGRAM

Day 1 – Physics and GUI Description

- Introduction on physics, modeling, material requirements

- Elementary test simulation

- Explanation of required input parameters: Material characterization tests

- Single layer forming simulation.

- Multi-layer forming simulation.

- Post-processing and presentation of results

Day 2 – Practical Exercise

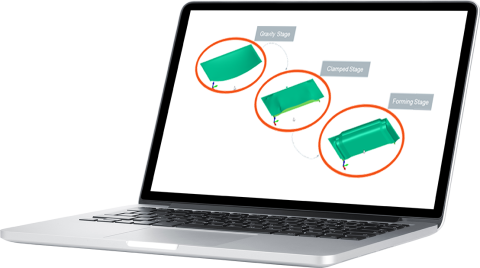

- Multi-stage simulation (gravity, forming)

- Trim Press Forming

- Plastic Blister Forming.

- Flattening tool: Initial flat pattern optimization

- Doubts and requests