PAM-RTM - Iso-Thermal Filling

Be able to model, analyze results and optimize through simulation standard injection or infusion processes performed at a constant and uniform temperature.

Be able to identify required data and to determine proper assumptions for simulations.

Be able to identify required data and to determine proper assumptions for simulations.

Audience

CAE engineers, Process engineers, Material engineers, Designers

Prerequisites

Basic FEA knowledge and basic composites material knowledge

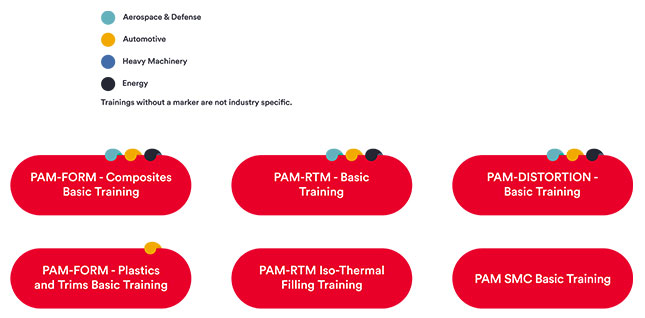

LEARNING PATH

SUGGESTED COURSES

DESCRIPTION

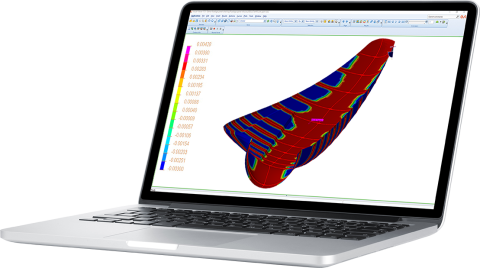

This training is meant for engineers responsible for designing manufacturing processes such as RTM/infusion for composite parts. This training relies on PowerPoint presentation and practical use cases executed on workstation. This training will allow the trainee to confidently create simulation models.

No suitable date or place?

Set up a private training

TRAINING PROGRAM

Day 1

- Introduction on physics, modeling, material requirements.

- GUI description and workflow Visual-RTM and Visual-Viewer.

- Shell model simulations: From CAD (1) to simulation with simple tutorials. The next concepts will be explained:

- Vents, air traps and gravity effect.

- Permeability and fiber orientation definition.

- Layer design manager.

- Channels and runners.

- Automatic process: Triggers and sensors.

- Air entrapment, gravity.

Day 2

- Solid model simulations.

- From CAD(1) to simulation with advanced tutorials. The next concepts will be explained:

- CPD and lay-up importation.

- Mesh of a complex laminates. Automatic mesh.

- Effect of draping on injection (Importation of fiber direction and laminates):

- Link with QUIKFORM on shell and solid model.

- Link with PAM-FORM on shell and solid model.

- Extra options: Flow optimization, porosity, overfilling and gravity.

- Fluid-mechanic simulations: Infusion, Core deformation, Light-RTM and CRTM.

- Design of Experiments and Optimization.

(1) is training course includes initiation to Visual-Mesh regarding the specific meshing needs of the treated models. However, it does not include a complete Visual-Mesh training that can be ordered separately.