List of Training Courses

VPS Automation Hackathon

Gain expertise in scripting techniques to streamline workflows, implement session executions, and craft efficient automation codes. Enhance your CAE engineering productivity and unleash VE's full potential with our comprehensive training.

Virtual Performance

VPS-FO-A-HACK

Advanced

IC.IDO - Integrate Basic Training

Learn how to use digital product design data and create a collaborative virtual mock-up environment to visualize, understand, and validate product packaging or integration concerns during the product development phase.

Virtual Reality

IC.IDO-FO-B-INT

Basic

IC.IDO - Build & Maintain Basic Training

Learn how to create a collaborative virtual mock-up environment to visualize, experience, and validate integrated digital product designs during the engineering of human centric assembly and service processes.Note: For onsite training in Bagneux a minimum of 3 participants are needed for the course to take place.

Virtual Reality

IC.IDO-FO-B-BM

Basic

IC.IDO - Advanced Training

Learn about advanced workflows and features that can be used to conduct intricate product integration and virtual build & maintenance validations.

Virtual Reality

IC.IDO-FO-A

Advanced

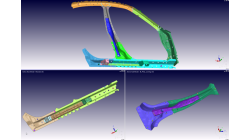

VSS - Seat Modeling

Learn how to prepare a seat model ready to be used for virtual performance testing for automotive industry.

Virtual Seat

VPS-FO-B-SM

Basic

VSS - Seat Trim Manufacturing

Learn how to design optimal cover flattened patterns without defects such as wrinkles. For automotive industry.

Virtual Seat

VPS-FO-B-STM

Advanced

VSS - Seat Static Comfort

Learn how to choose trim materials and shape in order to optimize seating comfort.for automotive industry.

Virtual Seat

VPS-FO-A-SSC

Advanced

VSS - Seat Dynamic Comfort

Learn how to identify seat ability to isolate its occupant from car vibrations. Learn to modify seat structure to avoid proximities between seat and car natural frequencies for automotive industry.

Virtual Seat

VPS-FO-A-SDC

Advanced

VSS - Seat Whiplash Test

Learn how to evaluate seat ability to protect its occupant from whiplash injury based on different protocols for automotive.

Virtual Seat

VPS-FO-A-SWT

Advanced

VSS - Seat Thermal Comfort

Learn how to evaluate seat thermal performance based on comfort score and energy consumption for automotive industry.

Virtual Seat

VPS-FO-A-STC

Advanced

Visual-Weld & Assembly - Automotive Spot Welding

Be able to translate the welding assembly process into a virtual model that can simulate this process and its effects. Understand differences in simulation concepts to support design engineering, early manufacturing engineering, and pre-series evaluation in decision-making. Be able to manage virtually assembly, repeatability, and assembly with sub-assemblies. Work with nominal parts, part shapes as manufactured & scanned parts. Be able to go from geometry to mesh to a simulation model to assess computed results. Be able to generate models that run stable, as fast as possible, still delivering accurate results

Welding & Assembly

SWD-FO-B-ASPW

Basic

Visual-Weld & Assembly - Automotive Seam Welding

Be able to translate the welding fabrication process into a virtual model that can simulate this process and its heat effects. Understand the benefit of combining rapid distortion engineering and welding process validation to minimize engineering & response time. Understand requirements and values delivered of rapid distortion engineering for complex designs (get a first idea and provide a quick distortion response to designs, design changes, clamps, etc.), refinement of the engineering approach with localized process simulation, and necessary steps towards accurate process validation and accurate process validation of complex designs. Be able to go from geometry to mesh to a simulation model to assessing computed results and generate models that run stable, as fast as possible, still delivering accurate results.

Welding & Assembly

SWD-FO-B-ASW

Basic

Visual-Weld & Assembly - Truck-Ship-Aero-Heavy Seam Welding

Be able to translate the welding fabrication process into a virtual model that can simulate this process and its heat effects and understand the benefit of combining rapid distortion engineering and welding process validation to minimize engineering & response time. Understand requirements and values delivered of rapid distortion engineering for complex designs (get a first idea and provide a quick distortion response to designs, design changes, clamps, etc.); refinement of the engineering approach with localized process simulation, and necessary steps towards accurate process validation and accurate process validation of complex designs. Be able to go from geometry to mesh to a simulation model to assessing computed results and generate models that run stable, as fast as possible, still delivering accurate results.

Welding & Assembly

SWD-FO-B-PSW

Basic

Visual-Weld - Dissimilar Weld Integrity

Be able to translate the entire fabrication process into a virtual model that can simulate this process and its heat effects; model a complex fabrication process that includes cladding, heat treatment, welding, post-weld heat treatment, and machining; go from geometry to mesh to a simulation model to assessing computed results and assess computed temperature, phase transformations, distortion, and residual stresses. Be able to generate models that run stable, as fast as possible, still delivering accurate results and understand and apply specific modeling techniques (fast transient & instantaneous welding) to assess large 3D structures)

Welding & Assembly

SWD-FO-B-DWI

Basic

Visual-Weld - Heat Treatment

Be able to translate the heat treatment process into a virtual model that can simulate this process and its heat effects; simulate heating, carburization if required, quenching and tempering; assess computed temperature, phase transformations, distortion, and residual stresses; go from geometry to mesh to a simulation model to assessing computed results and generate models that run stable, as fast as possible, still delivering accurate results

Welding & Assembly

SWD-FO-B-HAT

Basic

Visual-Weld & Assembly - Solver Parameters & Contacts

Understand contact modelling and how and when to use contact efficiently for rapid distortion and welding validation analysis. Understand solver parameters and its impact on performance and accuracy. Understand how to identify unhealthy simulations and how to get over it. Understand file structures and solution monitoring.

Welding & Assembly

SWD-FO-B-SCP

Advanced

Visual-Weld - Material Modelling

Understand material phenomena important for the modelling of the heat effects of welding & heat treatment. Understand which material properties are important to model heat effects of welding & heat treatment. Understand how to model material so that it can be used in a welding of heat treatment simulation. Understand how to generate own material databases starting from a public database

Welding & Assembly

SWD-FO-B-MM

Advanced

Welding Python for Visual-Environment

Apply python programming scripts unique to ESI software to enable automation and optimization of CAE Workflows. Utilize Python Libraries in both preprocessing, solving and postprocessing.

Welding & Assembly

SWD-FO-B-PVE

Basic

Welding Automation using Scripting in Visual-Environment

Develop efficient automation solutions to apply to your current challenges faced in your CAE workflows. Understand and apply the versatility and flexibility of Python scripting in Visual environment.

Welding & Assembly

SWD-FO-B-ASVE

Basic

Welding Automation using SDK-Batch

Learn how to leverage its command-line interface alongside the Python module VistaDb for streamlined task execution, optimizing efficiency in your workflows.

Welding & Assembly

SWD-FO-A-ASDK

Advanced