List of Training Courses

VPS Explicit - Basic Crash Modeling

Learn about and understand the basic aspects of crash simulations. Discover how to set up a simple component crash model step by step with all essential options, evaluate the results, and confirm their plausibility.

Virtual Performance

VPS-FO-B-BCM

Basic

VPS Explicit - Advanced Crash Modeling

Extend your know-how with advanced VPS options. Learn how to derive component simulations from full car simulations and combine different levels of detail. Learn to transfer simulation-/manufacturing results to a subsequent simulation. Learn to combine different load cases and disciplines in one simulation. Learn to analyze and improve the performance and robustness of the simulation.

Virtual Performance

VPS-FO-A-ACM

Advanced

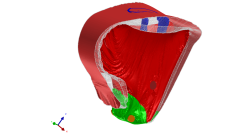

VPS Explicit - Dummy Models

Learn about and understand the variety of dummy models and how to utilize them. Learn to position and integrate a dummy model into a vehicle. Learn to set up a belt system with elaborated retractor options, such as a pyrotechnical pre-tensioner and load limiter. Learn to analyze the dynamic results, including the sensor output of a dummy model.

Virtual Performance

VPS-FO-B-CTDM

Advanced

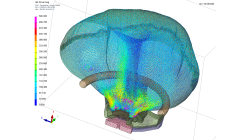

VPS Explicit - Airbag Modeling

Learn about and understand the basic aspects of airbag modeling. Learn to set up a simple Uniform Pressure airbag, how to add the definitions for gas dynamics (FPM) and analyze the results. Learn how to ensure your model accuracy by learning about the best modeling guidelines and practices.

Virtual Performance

VPS-FO-A-AM

Advanced

VPS Explicit - Airbag Folding with SIM-FOLDER

Learn about and understand the possibilities of airbag folding simulation. Learn to set up and perform a folding simulation step by step with a simplified airbag. Use the variety of folding tools of the SIM-FOLDER database and learn how to create new folding tools easily. Learn to parameterize the folding steps and use them in a chained process.

Virtual Performance

VPS-FO-A-AFSF

Advanced

VPS Explicit - Material Modeling

Understand the phenomena of individual material classes and learn which standard material models exist in VPS to describe this material behavior.

Virtual Performance

VPS-FO-A-MM

Advanced

VPS Implicit - Basic Training

Learn about and understand the general of a VPS model. Learn to set up and run a simple static linear or nonlinear static load case with VPS and evaluate the results.

Virtual Performance

VPS-FO-B-IBT

Basic

VPS Implicit - Linear and Non-Linear Statics

Learn how to create load cases for all static analysis types (statics, thermal, buckling). Learn how to chain different analysis types in one model.

Virtual Performance

VPS-FO-B-LNLS

Advanced

VPS Implicit - Dynamics (Modal Analysis and NVH)

Learn how to set up a modal and frequency response model. Learn about typical NVH results and how to obtain and evaluate them.

Virtual Performance

VPS-FO-B-DMA

Advanced

VPS Implicit - NVH - Automotive Low Frequency Interior Acoustics

Learn how to set up a coupled frequency response analysis for structure.

Virtual Performance

VPS-FO-A-ALFI

Advanced

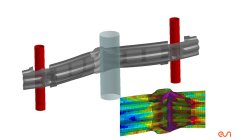

VPS Implicit - Boundary Element Method

Learn how to set up a vibroacoustic BEM model for a given structural mesh. Learn how to evaluate results on the BEM surface and the exterior.

Virtual Performance

VPS-FO-A-BEM

Advanced

VPS Implicit - Transmission Loss

Learn how to set up a transmission loss model for a given structural and trim mesh. Learn how to evaluate transmission loss results.

Virtual Performance

VPS-FO-A-TL

Advanced

Visual-Mesh for VPS - Basics

Learn how to use Visual-Mesh for VPS. Discover how to import, clean-up and mesh different geometries that can be used for crash, safety, statics, dynamics or NVH applications.

Virtual Performance

VPS-FO-B-VMVE

Basic

Visual-Crash PAM for VPS - Basics

Learn how to use Visual-Crash PAM to create a VPS model. Discover how to build a VPS model from scratch or modify an existing model. All the tools you will see are optimized for the solver functionalities, to improve productivity.

Virtual Performance

VPS-FO-B-VCVE

Basic

Visual-Crash PAM for VPS - Advanced

Extend your know-how with advanced options in Visual-Crash PAM. Lear how to use more advanced options and how to be more efficient in the creation and verification of your VPS model.

Virtual Performance

VPS-FO-A-VCVE

Advanced

Visual-Viewer for VPS - Basics

Learn how to use Visual-Viewer for VPS. Discover how to visualize animations, analyze results, plot curves, and make the most effective use of Visual-Viewer’s functionalities in your day-to-day work.

Virtual Performance

VPS-FO-B-VVVE

Basic

VPS Python for Visual-Environment

Apply python programming scripts unique to ESI software to enable automation and optimization of CAE Workflows. Utilize Python Libraries in both preprocessing, solving and postprocessing.

Virtual Performance

VPS-FO-B-PVE

Basic

VPS Automation using Scripting in Visual-Environment

Develop efficient automation solutions to apply to your current challenges faced in your CAE workflows. Understand and apply the versatility and flexibility of Python scripting in Visual environment.

Virtual Performance

VPS-FO-B-ASVE

Basic

VPS Automation using SDK-Batch

Learn how to leverage its command-line interface alongside the Python module VistaDb for streamlined task execution, optimizing efficiency in your workflows.

Virtual Performance

VPS-FO-A-ASDK

Advanced

VPS Workflow Automation in Visual-Environment (Visual-SDK)

Gain expertise in scripting techniques to streamline workflows, implement parametric session executions, and craft efficient automation codes. Learn to develop customized GUIs with user friendly Visual SDK interface.

Virtual Performance

VPS-FO-A-WFA

Basic